SLEEVER: The innovative pioneer of the shrink sleeve technology

THE SLEEVER GROUP

An innovative driving force in heat-shrink sleeve technology, the company draws on over 45 years of expertise, passion and innovation in the service of brands, guided by the alliance of science and emotion: science fuels emotion, emotion guides science.

Their 1000 expert employees from 25 nationalities serve clients and are dedicated to meeting commitments on a daily basis. Present worldwide, their international footprint is combined with the human values of a Family Company.

Their 14 industrial sites on 5 continents (Europe, Africa, Asia, North America, South America), offer a global vision combined with a local presence in order to accompany clients on diversified markets. They are proud to be a partner of their product launches in over 50 countries.

Teams of multi-skilled engineers and technicians work together to find packaging and labeling solutions to meet the needs of consumer product industries. Their multidisciplinary R&D teams have allowed them to build an extensive offering: their trademarks and patents (more than 500) clearly demonstrate this.

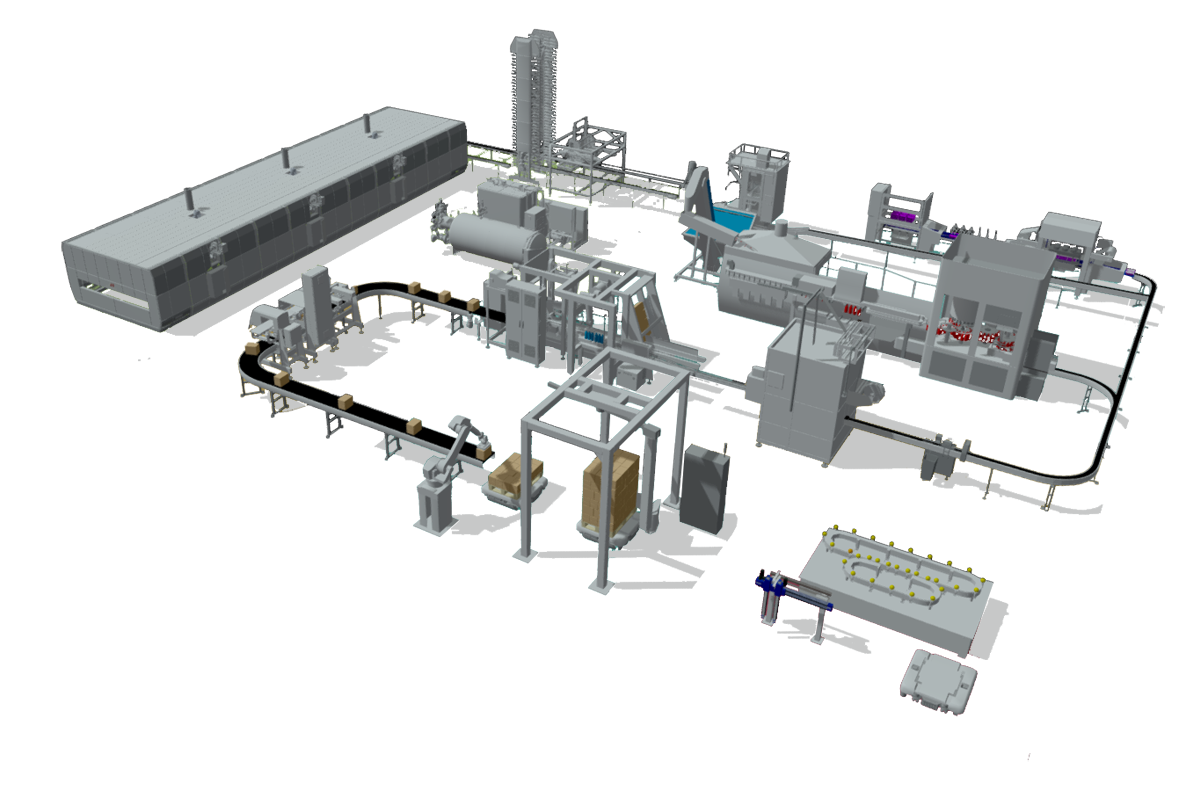

They master the entire value chain: from film formulation, printing, converting, capital goods manufacturing to services.

SLEEVER MACHINES GROUP

With over 1300 machines installed worldwide and 45 years of expertise, they are a major stakeholder in the shrink sleeve industry. The Sleever Group's mastery of the entire process has allowed them to offer expertise and optimal implementation. Their manufacturing plants and expert centers on five continents make customer service key to their success: "We think global, we act local".

Facilities / Services SLEEVER

With their unique expertise in this technology, they have put it to work in capital goods, from design to manufacturing to commissioning.

They accompany you throughout the life of your products.

Equipment Designed for Operators

Their machines offer easy-to-use features that allow operators to run them and ensure performance with simple, safe, and tool-free operations. The graphic and tactile interfaces are enriched with modules such as preventive maintenance or multilingual technical documentation. The remote access modules allow keeping a constant link with their hotlines and expert centers around the world.

An Original, Agile, and Interactive Design

A monoblock design with reduced floor space, integrated electrical cabinets, and a transparent 360° enclosure optimizing the workspace. A wide range of modules offers additional functionality, depending on the product requirements. Thus, their offer adapts to the configuration of plants and needs.

Industrial Solutions for All Markets

Whatever the configuration of packaging lines, the challenges of markets, or the specificities of projects, they have a range of adapted equipment: expert machines, specialty machines, and stand-alone machines will provide the industrial solution needed. Expert machines for markets ranging from food to beauty, specialty machines for specific uses, from pharmaceuticals to makeup, stand-alone machines for specific industrial needs such as FabLab and service providers.

- Eco-designed

- Operator friendly

- Optimized footprint

- Monobloc and modular conception

Specialty expertise: a turnkey solution for the success of your projects

- Proven experience

- Modularity for the various applications

- Easier driving for operators

- Local technical support

- Autonomous and mobile

- Safe for operators

- Reduced energy consumption

- Proven experience

-

The standalone offer

The standalone offer

The standalone offer

The standalone offer

-

Ready-to-use equipements expertise

Ready-to-use equipements expertise

Ready-to-use equipements expertise

Ready-to-use equipements expertise

-

Specialty equipments

Specialty equipments

Specialty equipments

Specialty equipments

https://www.geppia.com/en/equipment-and-services/packaging-production/primary-packaging/bottle-marking-coding-labelling/sleever#sigProIdf82aec6cb4

LDPET sleeve for infrared/hot air retraction, and with light barrier

Friday, 18 November 2022Sleever Machines, a new interactive digital platform

Monday, 19 July 2021Contact this company

Positioning on the line

Functions & Applications

10-A44

10-A44