Packaging manufacturing machines, filling and capping machines for bottles and cups

Aseptic bottle filling

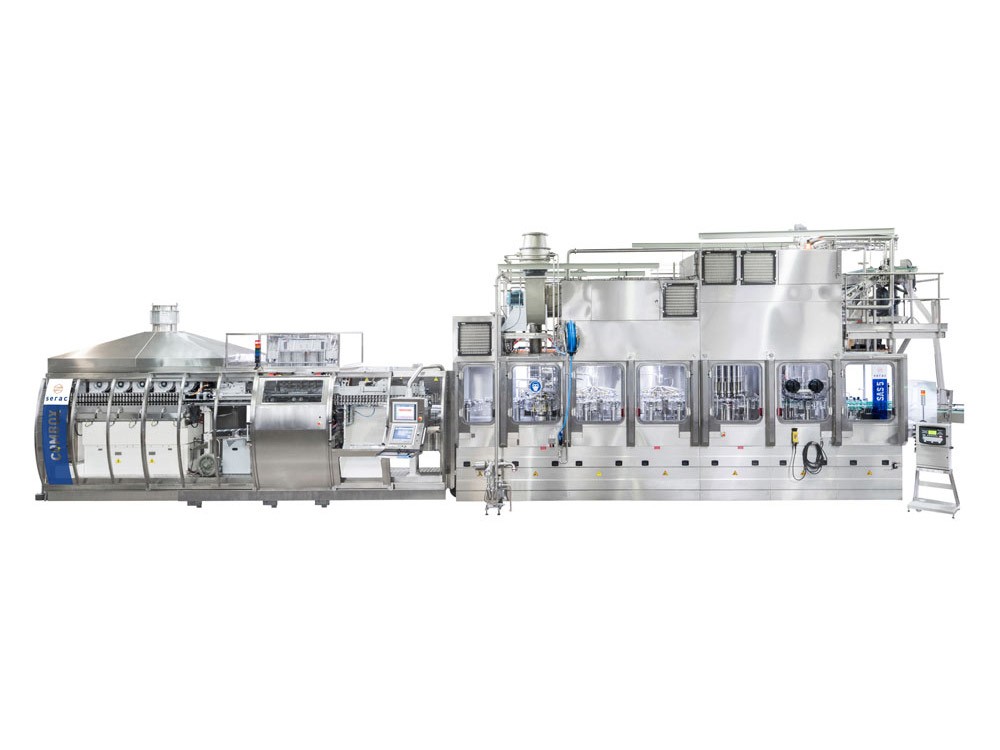

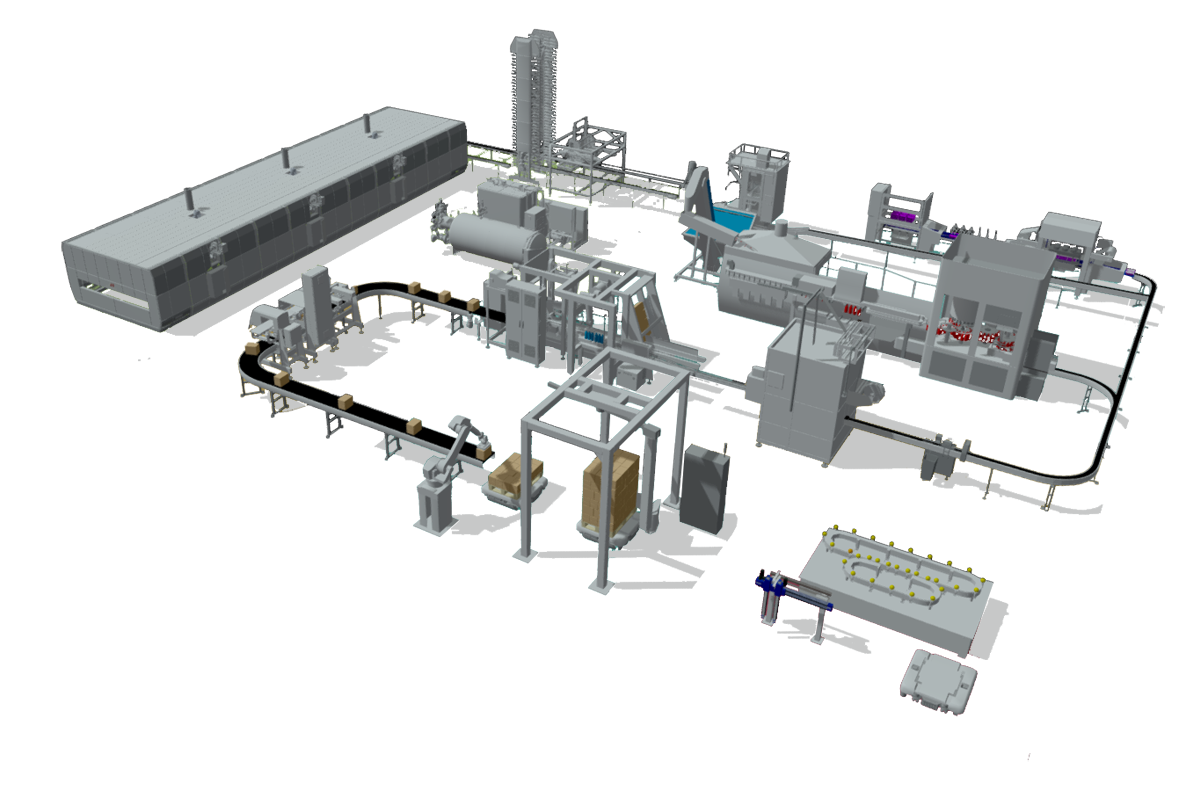

Serac has succeeded in combining its linear PET blow-moulding machine (SBL) and its rotary weight filler in a block version (called Combox).

By the end of 2017, about 15 Combox units had been installed in Europe, America and Asia. Today, the Combox is available in an Aseptic version. It opens up new prospects for dairy and beverage manufacturers, providing them with a low to medium-speed solution for neutral and acidic pH products, capable of handling up up to 12,000 PET bottles per hour per liter, and up to 18,000 PET bottles per hour on small 250 ml formats.

An affordable aseptic blow-moulding and filling solution

Until now, the aseptic market has had a limited choice of integrated medium-speed filling lines: on one side, cartons; on the other, bottles with high-capacity blowing-moulding-capping lines.

Facilities / Services Serac

- Combox: Blow molding, filling and capping unit

- Roll N Blow: machine for manufacturing bottles from a roll of plastic sheets.

- RB: Rotary weight filling machine.

- SAS 4: Aseptic packaging line for dairy products and beverages.

- Linea, Neo: Volumetric filling machines for preformed jars.

- Canopy: Rotary filling machine for vegetable oil.

Remplissage et bouchage de bouteilles

Soufflage de bouteilles

https://www.geppia.com/en/equipment-and-services/packaging-production/primary-packaging/extrusion-blow-molding/serac#sigProId7297eed991

Dosage: when creativity and technology meet

Thursday, 07 March 2024Positioning on the line

Functions & Applications

10-C30

10-C30