Kriska Industrie offers technical solutions for feeding and denesting operations for any flat articles such as paper sheets, cardboard pieces, leaflets, etc.

The Kriska friction feeder helps you to insert sheets, cardboard pieces, leaflets, flyers, booklets, labels, envelopes, etc.

Then, drop them onto a conveyor, a lug chain, into boxes or trays at a speed of 300 cycles per minute, depending on the products and the way they need to be delivered.

The feeder is equipped with a step motor in its electrical cabinet.

A stack of products is placed in the feeder magazine above the friction belt. The friction belt drives the products one by one from below the stack. The following products are held back by the retaining roller. The product is then driven forward between two conveying belts to the exit end. When the sensor detects the product, the conveyor stops. The product is ready to be ejected.

After receiving the electrical signal, the conveyor ejects the product and drives another one.

The feeder exit can be either horizontal, vertical, or both, according to the environment specifications.

Standard lengths are 400mm, 600mm, or 800mm.

Facilities / Services KRISKA INDUSTRIE

- Horizontal feeding

- Vertical feeding

- Made-to-measure feeder

- Optional devices: counting, barcode reading, printing, batching process

Contact this company

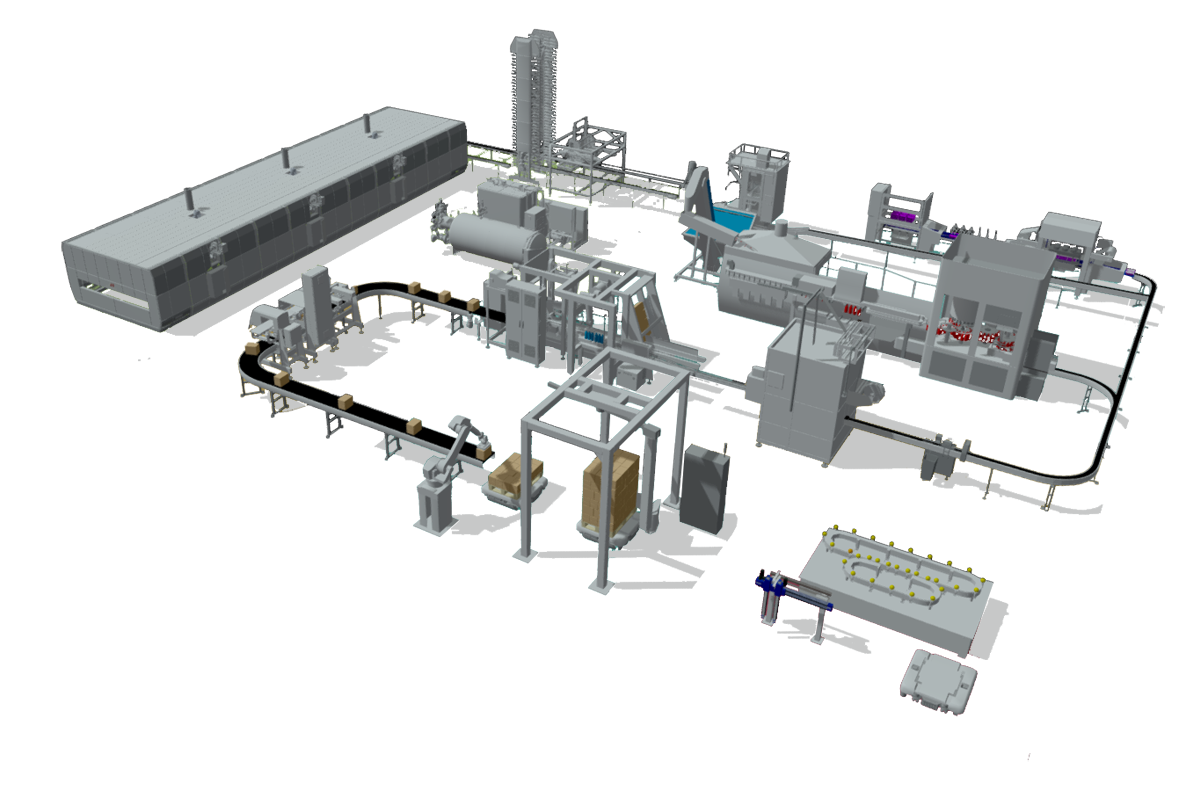

Positioning on the line

Functions & Applications

10-A28

10-A28