Nowadays, consumers are looking for real "homemade" products so taste and appearance are key factors in industrial food production.

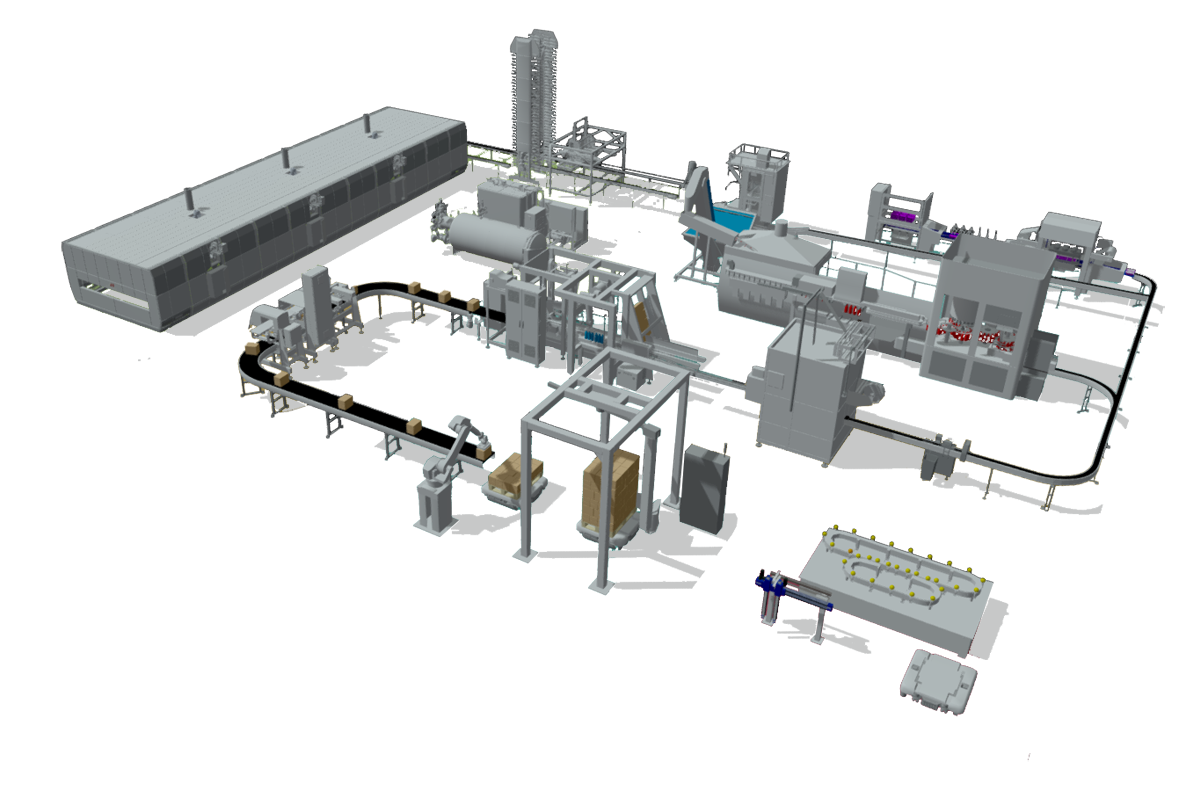

Specialized in the entire process for biscuits, pastry, bakery, confectionery, etc... Procys steps in from the moment products leave the production system (oven, deep fryers, moulds) until the final packaging process.

From the beginning of your project, we take into account the particularities of your request and we built, together, based on our well-established principles and modules, an adapted, reliable, simple and efficient solution which will meet your needs.

Facilities / Services PROCYS

Procys offers you unique solutions, adapted to your needs !

Handling

Handling the flow of fragile products at high speed in our core business. We help you in your line industrialization projects and provide different solutions :

Conveying systems : From basic cooling conveyors to distribution and indexing applications, Procys offers solutions including belt conveyors and bends, modular belt conveyors, slat or chain conveyors for plates or moulds, and elevators and troughs for bulk products.

Stacking systems : To feed machines such as traditional sandwich or packaging machines, it is necessary to stack the biscuits. There are two systems for placing biscuits : penny stacker & rotary stacker. We can help you to define the most appropriate solution for your production line taking into account the product itself, capacity and application.

Merging / Diverging : Procys offers you the possibility to combine two lanes into a single lane without collisions or to distribute products from a single lane to multiple lanes.

Row distribution : Products are distributed in rows to feed the packaging machines.

Turning device / Indexing : From products arriving in lanes at random, our systems can organize a constant pitch that will allocate precise positions and allow to load the chain of a packaging machine, for example. With this kind of system, products are handled with no contact between products.

Demoulding : When leaving the oven, products are in pans or lying directly on the oven belt, we proceed to the demoulding row by row or directly pan by pan. Several types of demoulding devices are available, depending on products and their fragility, using either aspiration or claws.

Dynamic buffer systems

An accumulator makes it possible to accept incoming production at a different rate from outgoing production.

An accumulator manages flows between two machines

It allows for example to separate the operation of a manufacturing unit from the packaging area. Even if the packaging machine stops, the processing machine can continue to operate with the same capacity. The packaging machines then operate at a slightly higher rate to absorb the accumulated products.

We can provide different types of buffers depending on the needs and configuration of the lines. Some technologies allow optimizing the space in height or in length, others allow to reorganize the products in the same operation. The key issue is to ensure independent product flow between two machines.

Processing

Dressing dough before oven, dosing toppings on products or in moulds, but also in-line with a sandwicher capper for biscuits / macarons or fillings for pastries, Procys provides an answer to your issue.

Dough depositors : We offer depositors to dose dough in molds cavities or directly on the oven belt. Possibility to dose sponge cakes, macarons, “boudoir” biscuits, savoiardi, pastry dough, madeleines, cake or muffin dough, etc... A standard system can be adapted to your application, taking into account factors such as : type of dough (viscosity, aeration, temperature, etc.), quantity to be deposed, line capacity, and width of oven.

Dosing systems : Dosing of fillings on or in products, different applications are available : dosing of cream, jam, caramel or marshmallow on a tartlet, dosing of sauce, fruit compote, yogurt etc... Procys offers a complete range of machines tailored for your application in terms of filling and capacity and will discuss with you the best options for your production needs. Dosing can be carried out continuously with a depositing head following the product throughout the dosing process. We can deposit in single or multiple shots, in layers or using a personalized layout (2D or 3D).

Capper sandwiching machine : The sandwiching capper is used for the production of sandwiches using round, square or rectangular biscuits. Available in short or long versions, it can accommodate up to four mobile depositing / capping heads. Dosing of cream, jam, chocolate, caramel, mallow, etc... using spot or layer technology with motion-tracking devices. No product / no dosing function available. Possibility to make triple sandwich (e.g. alfajores), co-deposit with several flavours in one product or different flavours in the same row. The machine is available in an industrial version or semi-industrial version.

Filling / Injecting machine : Different types of filling machines: in-line injector or injecting machine with product feeding by transversal conveyor. Manual, semi automatic or fully automatic products feeding system. Vertical or lateral injection using one or more injection points. Filling with cream, jam, chocolate, caramel, or fruit puree for donuts, croissants, cakes, brioches, madeleines, muffins or éclairs.

Packaging

We prepare products for packing in individual packs or batches, with or without trays. We also offer a total solution including tray denesters, tray loading and feeding into packaging machines.

Tray denesters : Procys offers several types of tray denesters for the complete range of trays, capacities and applications. We will discuss with you the most appropriate system for your production requirements. The main advantages are : large autonomy, horizontal store, motorized lanes to facilitate loading.

Tray loading systems : Creation of product batches using pick and place devices or robots.

Tray accumulators : The accumulator manages flows between two machines. For example it separates the operation of the primary packaging zone from the secondary packaging. Even if the secondary packaging stops, the primary packaging machine can continue to operate with the same capacity. The secondary packaging machines then operate at a slightly higher rate to absorb the accumulated products.

Online printing system

Procys makes possible the customisation of your products with digital printing.

The system can print with one or two colours and works with natural food inks : brown based on caramel & magenta based on red beetroot.

This technology can be declined in two applications :

1 to 4 lanes version : mobile device allowing to print from 1 to 4 lanes. This flexible and scalable system can be moved on several lines. It can be installed just prior to a flowpack to print just before an individual packaging.

5 lanes and more version : fixed system installed before or after the oven. There is one print head per product lane.

Innovative & Trendy : Product customization is currently very trendy but the ability to carry it out industrially and in a flexible way is innovative. The system allows changing the image or the text without any mechanical tooling (controlled exclusively by software).

Differenciation through food printing : Manufacturers are focusing on differentiation and added value. With printing, there are many applications possible including customization for direct-to-consumer advertising or to deliver a message, to highlight the brand name or simply for fun etc.

Contact us now ! info@procys.eu

Our team is at your disposal to meet you, understand your needs and find together the most suitable technical solutions.

-

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

-

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

-

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

-

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

Procys, Solution Designer

https://www.geppia.com/en/suppliers/item/132-procys#sigProIdcc80b59575

Contact this company

Positioning on the line

Functions & Applications

HALL 4 / E59

HALL 4 / E59