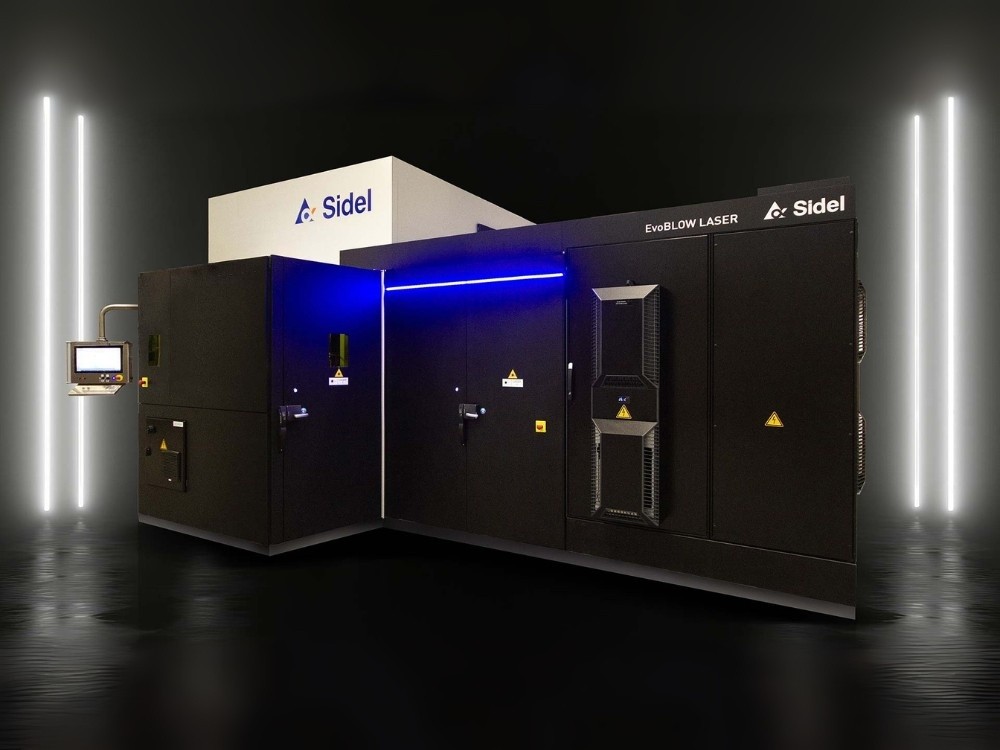

EvoBLOW Laser: Sidel ushers in a new era for PET blowing |

SIDEL

"Sidel has been leading the way in blow moulding technology for over 45 years. At drinktec, we are now unveiling the world’s first fully industrialized laser solution that completely changes the game. Our pioneering commercial blower for PET revolutionized packaging in 1980. Today, the EvoBLOW Laser will once again revolutionize the sector by redefining the concept of line efficiency and creating new lightening possibilities.” Pietro Cassani, President & CEO of Sidel.

From halogen to laser: a sectoral flip

After decades of halogen technology with no viable alternative, the industry recognizes the limits of this heating and overcomes them with the new laser solution, in a context of increased pressure on costs, sustainable development and operational agility.

Lighten without sacrificing resistance

The precision of the laser allows for both lighter and stronger containers. While halogen solutions heat in large areas, the EvoBLOW Laser uses up to 36 heating lines (versus eight areas on a comparable solution), ensuring unparalleled control of thickness across the entire container.

This mastery allows for lightweighting, including on premium bottles, thanks to the creation of "powerful rings" invisible to the consumer, replacing traditional "geometric grooves", with more design freedom. It extends the relief to previously inaccessible areas, notably under the collar.

In addition, the machine facilitates the blowing of a wider range of formats and shapes from the same preform, which simplifies logistics.

Quality "on the first try", regardless of the conditions

Halogen solutions are sensitive to the environment and require frequent and complex adjustments. Conversely, laser technology is not affected by its environment: a total and constant quality is obtained with unprecedented ease, thanks to a single process adjustment per heating line (intensity). Each preform, from the first to the last, receives the exact thermal profile required, regardless of ambient temperature variations.

Line performance and operational readiness

The EvoBLOW Laser offers a cold start and high robustness: the laser oven is always ready, without warm-up/cool-down times, and without "sleep" mode to keep it warm, eliminating downtime at each stop/restart. In addition, the live speed modulation allows the snowblower to automatically and temporarily adjust its speed in real time according to line conditions.

Ease of use, security and maintenance

Knowing that the machine restarts instantly while maintaining consistent quality reduces stress related to unplanned stops. The cold oven technology allows quick access without waiting and without risk of burning. Adjustments are made through an intuitive "touch" interface, and maintenance is facilitated by the absence of fans and filters, as well as the long life of the laser diodes.

rPET and environmental gains

The solution favors the increased integration of rPET, a material less sensitive to material variations; when adaptations are necessary, they are made immediately. The faster heating and higher preform temperature allow optimal elongation. Compared to conventional solutions, the technology reduces preform waste and benefits from a smaller furnace.

Field validation at Refresco

Supported by a strong partnership, the technology has been field-tested at Refresco with remarkable results. As Refresco’s Supply Chain Director, Coert Michielsen points out: "After 45 years of halogen technology, we are now entering a new era. I am convinced that laser oven technology will become the new normal.”