A series of new videoconferences for continuous learning and refreshing your mind

With two editions already under its belt, the Process & Packaging Machines Forum offers you several webconferences to watch in replay!

Multiple short and inspiring sessions, perfect for dipping into or diving into, to enhance the performance of production and packaging processes.

On the agenda: feedback from experiences, trends, and innovations on current topics, presented by passionate guests."

Replays of the second edition

9:30-10:30 am CEST (Paris)

Producing better with less

New consumer expectations and a smaller carbon footprint in the production phase: where are the synergies and potential contradictions?

What strategy should you adopt, depending on your company's size and sector of activity?

Our guests will launch the debate by sharing their initial experiences.

Come and share yours!

Aiming for zero impact - Episode 2

Producing better with less

After an initial overview of packaging ecosystem initiatives, this second Think Tank discussion will focus on the environmental impact of the production phase.

Through the experience of two manufacturers of different sizes and from different sectors, and the contribution of a member of the GEPPIA, we will try to identify the common challenges and the particularities to be taken into account to rapidly achieve significant results.

Join the debate!

Aiming for zero impact - Episode 2

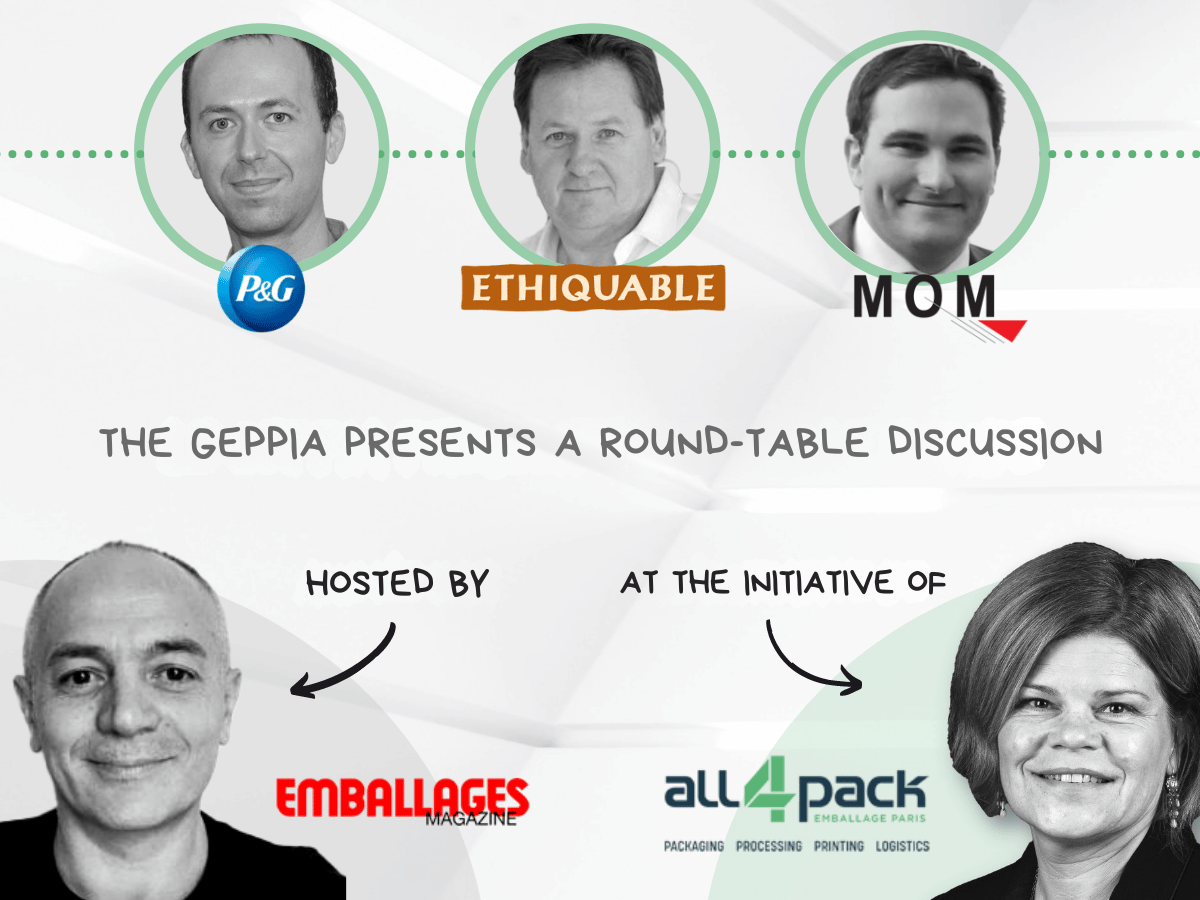

Round-table opening event hosted by our partner

Round table presented by Adeline Vancauwelaert, Director of the All4Pack trade fair, and hosted by Tiziano Polito, Deputy Editor-in-Chief at Emballages Magazine, with :

- Guillaume Lebert, Sustainability Senior Scientist, Procter & Gamble

- Christophe Eberhart, Co-founder, Éthiquable

- Louis Derangère, CEO, MOM Packaging

11:15-12:00 CEST (Paris)

- We can rest assured...

Telemedicine saves machines too

To survive, a person having a heart attack must be rescued in less than 5 minutes.

In the factory too, every minute of downtime counts. And it's the OEE that's at stake.

Find out how 1Blow helps your blow-moulding machines and enables you to monitor their state of health, thanks to the telemedicine solutions developed with B&R.

We can rest assured...

Telemedicine saves machines too

On my right is the emergency doctor, on my left the connected watch. When technology brings the two together, it saves lives.

Let's imagine a single person suffering from a heart attack. His or her watch could automatically alert the neighbour at the same time as the doctor, so that first aid could be administered as quickly as possible.

The watch could also detect an episode of fibrillation, and warn the patient before the heart stops.

Monitoring, automated alerts, remote diagnosis. The ingredients are the same for connected maintenance.

Olivier Perche and Julien Koubbi explain how they can intervene remotely to restart a machine, and how you can take control of prevention to prevent a downtime.

Replays of the first edition

12h30 AM - 01h00 PM CEST (Paris)

- IIoT platforms

The factory goes through analysis

When the factory starts to talk, it unveils surprising sources of improvement.

A practical illustration with Hellenic Dairies, where digital continuity led to unexpected increase in operational and environmental performance.

Laurent Couillard, Founder and CEO of InUse

IIoT platforms

The factory goes through analysis

With the IIoT, the factory can finally start to talk. And tells us what's keeping it from improving.

But for us to help, it has to speak clearly.

Collecting data is one thing; reading and returning it in a way that's easy to understand is quite another. The power of an IIoT platform depends on the quality of this analysis.

But it is also through an overview of factory’s problems, and the ability to solve them all in the same environment, that one can quickly and lastingly improve performance in production.

Laurent Couillard helps discover how digital continuity allows to break through the glass ceiling of operational and environmental performance.

Access to the videoconference: here

11h45-12h15 AM CEST (Paris)

- Sterilization

Industry 4.0 : What intelligence do you aim to develop?

The case study of sterilization

Where does the intelligence in a process come from ? From man or machine ?

For Steriflow the answer is clear.

An experiential review from two years of intensive co-construction for a new generation of autoclaves designed to meet the very specific needs of the sterilization industry.

Matthieu Cillard, Steriflow's Sales director

and David Castronovo, sales engineer at IFM

Sterilization

Industry 4.0 : What intelligence do you want to develop?

The case study of sterilization

The intelligence of a sterilization process is developed in the laboratory; autoclaves are only there to reproduce it.

Autoclave 4.0 is not intended to be intelligent in the sense of being autonomous in decision-making.

On the contrary, it is an autoclave placed under closer monitoring, reporting back to humans in real time to be better corrected by them.

And in this sense, its strong points are the reliability, security and relevance of the data it returns to the user.

Matthieu Cillard and David Castronovo share their vision of what the sterilization function could be, in practice, within a connected factory.

01h30-02h00 PM CEST (Paris)

- Automated logistic centers

When the rejection rate for pallets goes sky high

With automated systems, tolerance is no longer an option.

Discover how to wrap your pallets in order to make sure they will pass through the doors of a 4.0 warehouse.

Yohann Gaidon, Thimon's Sales director

Automated logistic centers

When the rejection rate for pallets goes sky high

Distribution centers and e-business platforms have gone for full automatization in their warehouses. They take delivery of pallets and handle them, manage their inventories and prepare their orders with digital tools and a minimum of human internvention.

Such a transformation has direct consequences on acceptance criteria for pallets. Requirements are increasing and leading to abnormally high rejection rates on the suppliers’ side.

New technologies = new dress code.

Learn how to identify and solve the main causes of non-conformity, by following a pallet of food products with Yohann Gaidon, from the manufacturer's end-of-line to the shelves of these new-generation warehouses.

Access to the videoconference: here

02h15-02h45 PM CEST (Paris)

- Shrink-wrapping

How to pack gigantic objects?

Wrapping a sofa, a picture window or a counter measuring several meters long, used to be done by hand. But times are changing.

Because your employees have better things to do, it is now possible to industrialize the handling and wrapping of XXL products, regardless of their shape, and offer them optimum protection during transport.

Surprise yourself by discovering these solutions!

Jérôme Galpin, Farbal's CEO

Shrink-wrapping

How to wrap gigantic objects?

XXL products are usually very valuable. And often fragile too.

And yet, most of the time, they travel wrapped in a simple stretch film that does not protect them well enough, no matter the considerable efforts made by your warehouse staff.

Does that mean that XXL products do not deserve the love of packaging machine manufacturers ?

No.

They now have shrink-wrappers, shrink tunnels and sealing stations that match their size.

Jérôme Galpin proves that even giants can claim to have packaging worthy of the name.

Access to the videoconference: here

A digital event powered by the GEPPIA Lab', in partnership with: