SMC contributes to environmentally friendly water filtration in the athletes' village |

SMC

One of the village buildings, consisting of 26 apartments, is equipped with an innovative system for filtering wastewater from showers, kitchens, and toilets, allowing it to be reused. Thanks to NEREUS’s NEOSTEP® solution, this water will be purified to the point of becoming potable and will be used for flushing toilets, washing machines, cleaning, and irrigating green spaces. Additionally, this system will recover heat from the wastewater to heat sanitary water. The Cycle building aims to recycle 90% of its wastewater and reduce water consumption by 60%, while also minimizing energy consumption.

NEREUS NEOSTEP® uses dynamic filtration technology for very low energy consumption

Founded in 2013, NEREUS is a French leader in dynamic filtration. Unlike traditional frontal filtration where particles adhere to the filter surface, tangential filtration allows fluid to pass through the filter under pressure, limiting particle accumulation. Dynamic filtration is an innovative variant of tangential filtration, offering high permeate flow rates and significantly reducing clogging risks with high-shear rotating membranes. Moreover, this method consumes about 80% less energy, making it both an efficient and ecological solution.

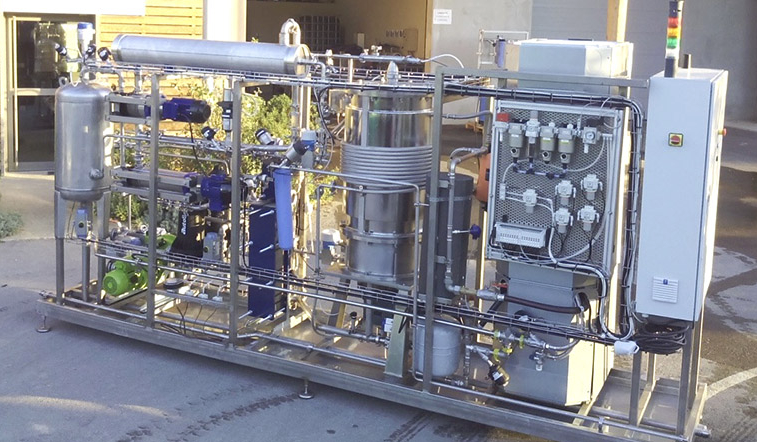

A Solution Available in the Heart of Cities

The compact NEOSTEP® treatment plant can be installed near usage sites, whether in parks and gardens, eco-neighborhoods, or sustainable buildings. These stations are designed to be compact and are tested in the workshop and delivered ready to use. Guilhem Molles, Technical Director of NEREUS, emphasizes: “We need compact and above all reliable components because it is crucial for us to avoid on-site repairs worldwide.” NEOSTEP® integrates the latest membrane technology enabling dynamic ultrafiltration associated with biological treatment followed by a final filtration stage by reverse osmosis. This solution can recover up to 497 kWh of heat per year, equivalent to avoiding the emission of 92 tons of CO2.

SMC: Listening and Product Differentiation

In the Olympic village installation, 12 water circuits are managed, each controlled by three angle seat valves. These valves ensure the opening and closing of the pipes for cleaning or taking them out of service if necessary. They are controlled by an SMC distribution island. Guilhem Molles highlights: “After testing distributors from many market players, we chose SMC’s offer due to its superior compactness and robustness. SMC’s waterproof pneumatic islands with their IP67 certification are essential because the installations must be cleaned with water.” These pneumatic islands are designed to withstand up to 5,000,000 cycles and feature IO-Link communication. Molles adds: “For more corrosive environments like coastal or tropical areas, we worked closely with SMC and used AMG water separators to eliminate up to 99% of water, as well as FRL AC 40D treatment units.”

A Solution for the Future

“This technology is very promising due to its low energy consumption. Although membrane prices remain high, the return on investment is estimated at around 5 years,” explains Guilhem Molles. But their costs are constantly decreasing. Currently, applications are mainly focused on industry and the tertiary sector, but the benefits of this technology suggest an expansion to wastewater treatment plants, which are heavy energy consumers. SMC supports NEREUS in all these developments.