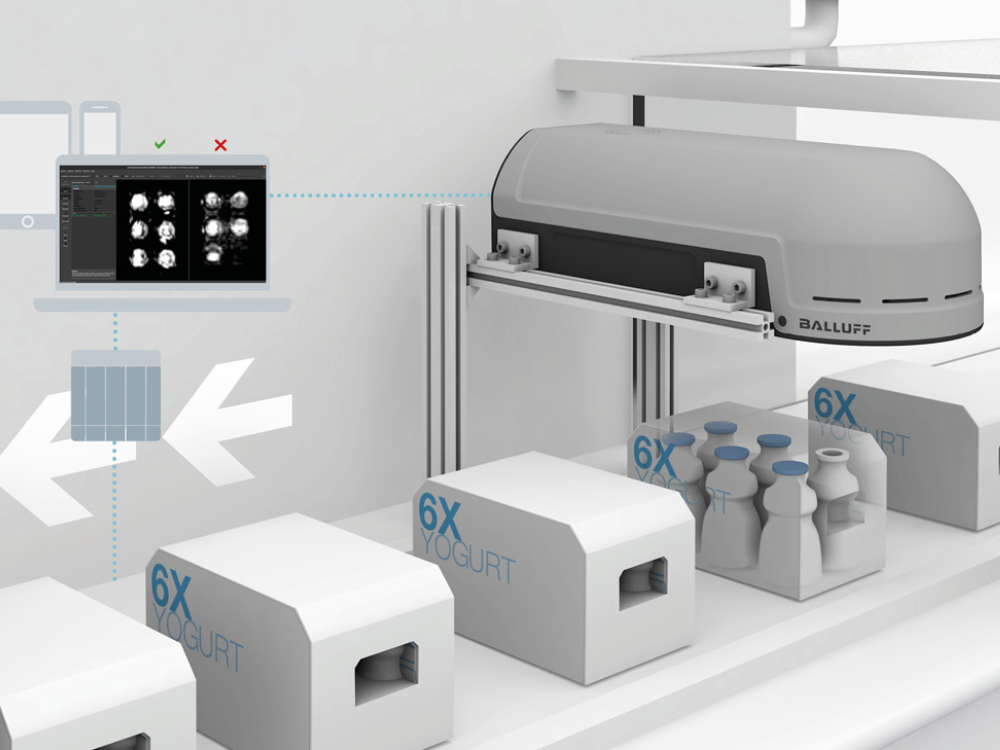

For increased quality assurance: Making the invisible visible |

BALLUFF SAS

This is precisely where Balluff's RadarImager comes in. This industrial 3D imaging system - based on radar technology - screens a wide variety of packaging. It allows you to scan all kinds of "hidden objects" to make anomalies visible. With the RadarImager you can check packages for completeness, product integrity or identify foreign objects and take quality control to a new level.

The advantages of the RadarImager

- Help identify impurities

- Increase process reliability

- Save inspection machine length

- Reduce recall costs

The RadarImager in practice

Whether for companies in the packaging, pharmaceutical or food and beverage industries, there are countless use cases for the RadarImager. This is a small selection of how you can ensure the quality of your products with the help of modern radar technology.

There are many different types of packaging in the food and beverage sector. There is a correspondingly wide range of quality assurance applications in this sector.

- Checking the contents of the packaging for completeness

- Detecting impurities and foreign bodies

- Checking packaging for integrity

- Checking the closures

- Detecting fill levels