PANEM INTERNATIONAL: Retarder-proving specialist since 1969 and cold solutions for the food industry

In 1969, PANEM INTERNATIONAL became the leading brand in proving through the invention and development of retarder-proving.

Since then, PANEM INTERNATIONAL has been able to adapt to all the requests of actors in the food-processing sector by meeting their needs with equipment that provides innovation, reliability, practicality but also profitability. All ranges are designed to ultimately work on the quality of finished products: cabinet, cell, workstation, freezer, preserver, showcase.

With French-made products, PANEM is capable of producing both a series piece of furniture selected from our catalog as well as tailor-made equipment designed by our design office, PANEM INTERNATIONAL knows how to meet all needs, whether for artisan bakers or industrial food-processing professionals with greater production capacities.

Drawing on the benefits of its many years of design and production experience, all processes related to the food industry are mastered, such as retarder-proving, proofing, deep-freezing, cooling, preservation, storage, maturation, crusting and many others…

For each need PANEM INTERNATIONAL strives to find the most suitable cold solution!

With a strong sales team relying on a network of distributors in France and for export, PANEM INTERNATIONAL covers an unlimited geographical area and can thus have sales and technical teams on site for sales, installations and maintenance.

The entire sales team is at your disposal to discuss your project.

Facilities / Services PANEM INTERNATIONAL

RETARDER PROVING

With first retarder-prover cabinets, PANEM permanently marked the artisanal bakery pastry market. In effect, this brought working comfort and regularity of production during one of the most important steps of bread production with mixing and baking.

By controlling temperature, humidity, by sheathing the airflow, PANEM provides a permanent proving control whatever the bread-making diagram is.

Fresh or frozen dough, single- or double-compartment cabinet, roll-in rack cell, it's up to you to choose and design your equipment.

POSITIVE STORAGE

Other solutions are supplied, especially for pastry chefs, regarding positive storage or deep-freezing.

PANEM adjusts cooling production according to the products to be preserved :

- Static cold for storage of raw dough in static bench-in refrigerators.

- Ventilated cold for storage of ready-to-eat products (with intermittent ventilation) or dough storage before proving (with continuous ventilation).

- Control of temperature and hygrometry (15°C/16°C -55%HR) for chocolate storage in ventilated bench-in refrigerators or fridge cabinets.

NEGATIVE STORAGE

PANEM is also involved in deep-freezing/preservation, with the aim of achieving positive or storage temperatures in a short space of time, stabilising a product at a given temperature or deep-freezing evenly.

-

Shock freezer and blast chiller cell

Shock freezer and blast chiller cell

Shock freezer and blast chiller cell

Shock freezer and blast chiller cell

-

Retarder prover cell

Retarder prover cell

Retarder prover cell

Retarder prover cell

-

HomeMade showcase – Europain

HomeMade showcase – Europain

HomeMade showcase – Europain

HomeMade showcase – Europain

-

HomeMade showcase – MH Colomiers

HomeMade showcase – MH Colomiers

HomeMade showcase – MH Colomiers

HomeMade showcase – MH Colomiers

-

HomeMade showcase – MH Lardenne

HomeMade showcase – MH Lardenne

HomeMade showcase – MH Lardenne

HomeMade showcase – MH Lardenne

-

HomeMade showcase – Maison Arnoult

HomeMade showcase – Maison Arnoult

HomeMade showcase – Maison Arnoult

HomeMade showcase – Maison Arnoult

-

Deep-freezer and preserver

Deep-freezer and preserver

Deep-freezer and preserver

Deep-freezer and preserver

-

Ventilated workstation

Ventilated workstation

Ventilated workstation

Ventilated workstation

PANEM, at the service of the food industries

Thursday, 22 February 2024Contact this company

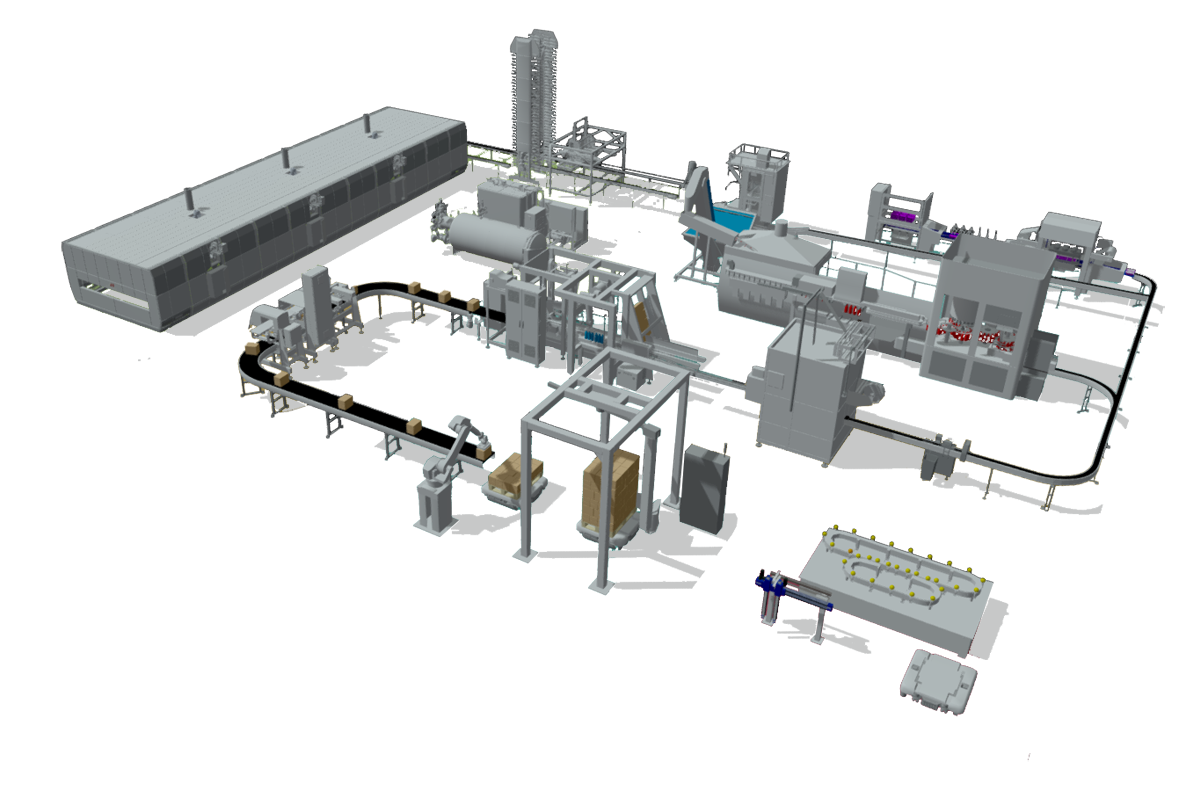

Positioning on the line

Functions & Applications

8-A35

8-A35