B&R AUTOMATION: Manufacturer of automation systems for machines and packaging lines

B&R Automation is a specialist in the automation of packaging machines and lines and is a partner of many leading packaging machine manufacturers and a member of the ABB Group’s Robotics and Discrete Automation business.

B&R Automation offers innovative solutions and a full range of services to support process and packaging suppliers in the development, implementation and maintenance of their machines.

Facilities / Services B&R AUTOMATION

The development of tomorrow’s adaptive and connected machines requires new technological convergences and highly integrated automation systems.

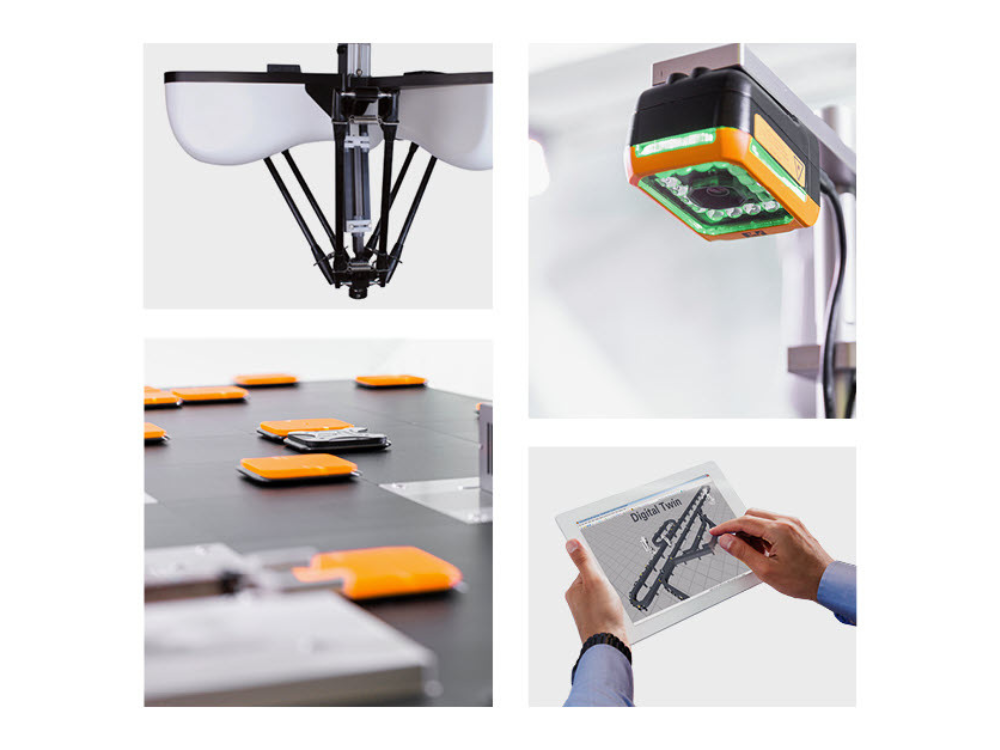

Integration extended to vision and robotics

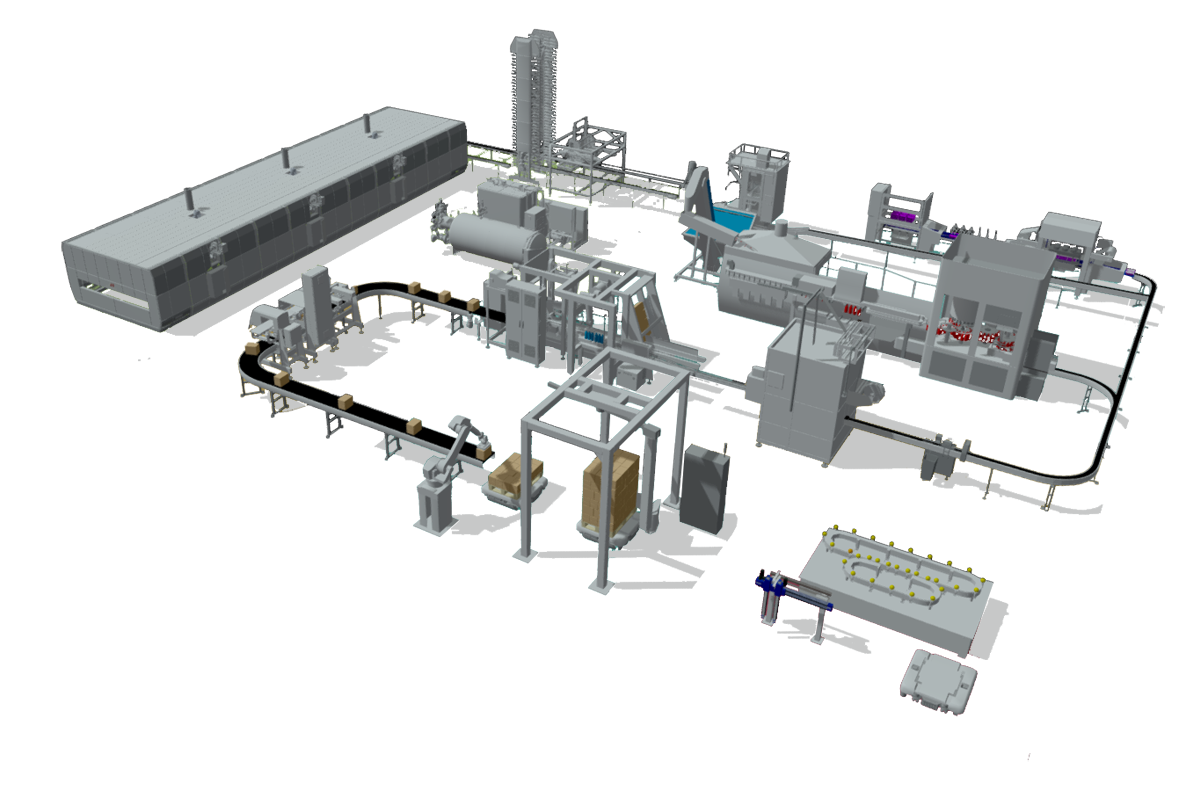

The solutions offered by B&R are based on innovative mechatronic concepts and very advanced technological integration. In addition to conventional automation components, B&R automation controllers also support vision application, track systems and robotic applications, all via a unified architecture. The gains in flexibility, space and performance generated by this integration open up new possibilities in production: automatic line reconfigurations without machine downtime, mass customization, predictive maintenance, etc.

Integrated vision: lighting control makes the difference

The integration of the vision system allows synchronization of the lighting with the microsecond image capture: a performance which makes it possible to obtain perfectly clear images with rapidly moving objects. In addition, the integration of the vision also allows changes to the automatic settings (LED orientation and color, for example) during machine operation. Several different articles can thus be produced efficiently on the same line.

Machine-Centric Robotics and track systems: one step closer to agile production lines

Up to now, integrating a robot into a machine and synchronizing these two systems was a long and complex operation. The Machine-Centric Robotics solution allows robots of various types to be integrated into B&R machine automation systems. This integration takes place without a dedicated robotic controller, a separate control cabinet, or a separate robotic application. Consequences: the robot integrates as easily as any other automation component, the space requirement in the machine is minimized, and the robot movements are synchronized with the other components (individual axes, sensors, etc.). the microsecond.

Perfectly integrated into B&R control platforms (PLCs, industrial PCs, etc.), the SuperTrak ACOPOStrak and ACOPOS 6D systems allow individual and precise transport of each product on production lines or within machines. The purely electronic switches made with the ACOPOStrak system make it possible to simultaneously produce several batches of different and reduced sizes (batch size one). All these characteristics facilitate the design of machines which can be easily reconfigured or even automatically depending on the packaging to be produced or the products to be packaged.

IT-OT convergence: a standard unifying sensor communication to the cloud

B&R integrates the OPC UA FX standard in its products. This standard provides the benefits of the OPC UA interoperability standard down to the field level. The homogenization of sensor communication to the cloud facilitates the deployment of Industrial IoT solutions for production monitoring or predictive maintenance.

Combo "track-robotisation"

-

Compact motor with on-board dimmer

Compact motor with on-board dimmer

Compact motor with on-board dimmer

Compact motor with on-board dimmer

-

Integrated vision

Integrated vision

Integrated vision

Integrated vision

-

Integration of ABB robots

Integration of ABB robots

Integration of ABB robots

Integration of ABB robots

-

OPC UA over TSN product lines

OPC UA over TSN product lines

OPC UA over TSN product lines

OPC UA over TSN product lines

https://www.geppia.com/en/equipment-and-services/partners-suppliers/components-and-systems/b-r-automation#sigProId9bc71f01c9

B&R: Your partner for adaptive machine design

Monday, 03 February 2025Automation systems for adaptive machines

Tuesday, 05 March 2024Contact this company

Positioning on the line

Functions & Applications

Stand 6-A76

Stand 6-A76