Discover the OPTI.Pure Zalkin range for production without plastic microparticles |

ZALKIN

The capping signed Zalkin

With 450 employees, including 380 in France, Zalkin is one of the leaders in the global bottle and container capping industry. With revenues exceeding $111 million in 2023, the company exports more than 80% of its production to more than 120 countries around the world.

Zalkin’s customers, whether they are small local businesses or global giants, operate in industries as varied as soft drinks, wines and spirits, dairy, agri-food, cosmetics, pharmacy, chemistry and household products. Zalkin’s solutions are designed to meet the specific needs of each customer, regardless of their market. From cap distribution to capping, quality control and cap processing, Zalkin offers a full range of dedicated machines, with speeds ranging from 800 to 120,000 caps per hour.

A strong commitment to the environment

Zalkin is actively involved with its customers in the fight against plastic pollution. Long before the entry into force of the EU’s Single-Use Plastics Directive, Zalkin has invested in technologies that enable optimal capping of new joint caps for the beverage industry. This co-development with capsule manufacturers and leading brands in the market, such as the Alma Sources Group for still and sparkling water, demonstrates Zalkin’s continued commitment to sustainable innovation.

Since 2021, Zalkin has extended its environmental commitment with a program of "reconditioned machines", allowing customers to reduce their carbon footprint while optimizing their investments. This initiative is part of a global approach to promote the circular economy and reduce the environmental impact of the packaging industry.

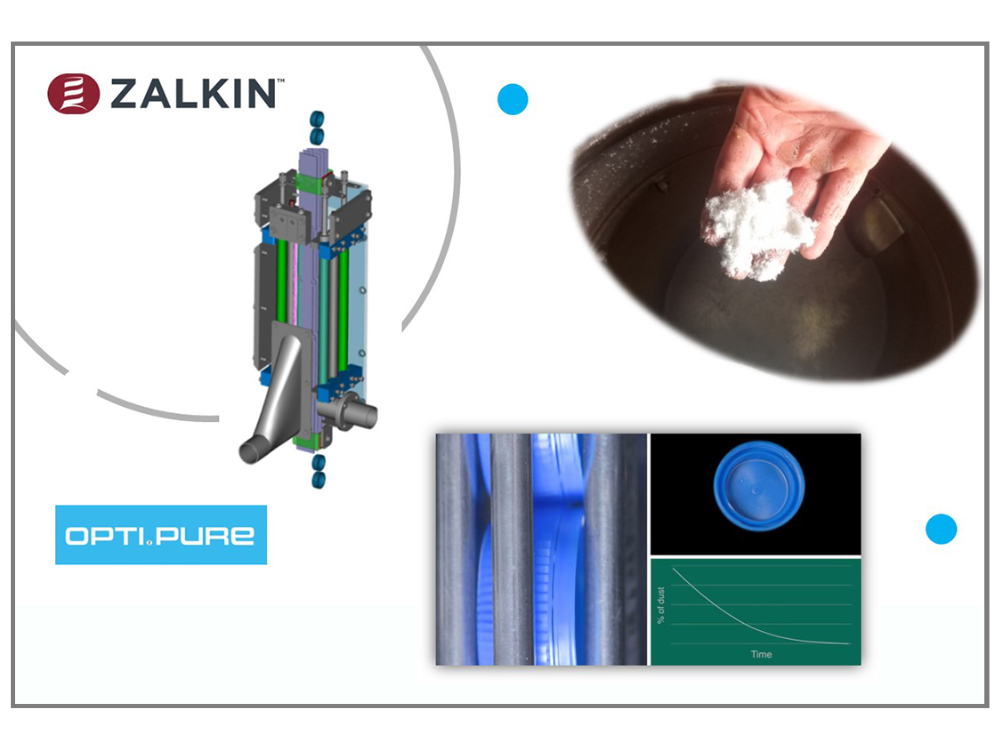

Zalkin launches its OPTI.Pure range, a leader in microparticle management

The widespread presence of plastic microparticles in our ecosystem generates major ecological disturbances, contaminates the food chain, threatens biodiversity and affects human health. Faced with this issue that concerns industry players, legislators and consumers, Zalkin presents its latest innovation: the OPTI.Pure range, dedicated to particle processing.

Zalkin offers a range of innovative solutions to meet the challenges related to the presence of plastic microparticles in production lines. Aware that handling capsules and caps generates secondary microparticles throughout the packaging process, Zalkin has developed tailor-made solutions adapted to your needs to eliminate these unwanted particles.

Zalkin’s OPTI.Pure range offers a multitude of solutions to ensure product integrity and maintain a clean production environment. These solutions include industrial vacuum cleaners equipped with H14 filters, ionization systems, fluidic conveyors with filtered air, as well as complete fairings and clean air injection systems.

Particle processing: a comprehensive and proven approach

Thanks to production line audits, laboratory tests and recognised expertise, Zalkin offers solutions adapted to each specific configuration. Zalkin’s particle processing system ensures up to 99.9% reduction in microparticles, ensuring product integrity and compliance with the highest standards.

In a context where the fight against plastic pollution has become a global priority, Zalkin’s OPTI.Pure range represents a significant step forward in the management of plastic microparticles in production. By offering complete solutions, Zalkin is committed to supporting companies in their transition to more sustainable and environmentally friendly production practices.

Join us at CFIA 2024 from March 12 to 14 at booth C40 Hall 10 to discuss all these topics!