Innovative solutions for the food industry and energy management |

SEW USOCOME

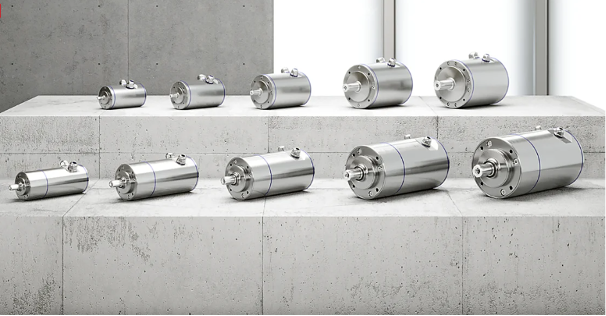

New range of stainless steel motor eductors for all your food applications

SEW USOCOME has designed a brand new range of stainless steel gear motors specially adapted to the requirements of the food industry. Already available in different sizes and configurations, these solutions meet many applications.

The new RES.. 7 spur gear motors and KES.. 7 and WES.. 9 stainless steel are designed to ensure impeccable hygiene, high efficiency and long service life, meet the specific needs of the food industry.

KES37 and RES37 stainless steel gear motors

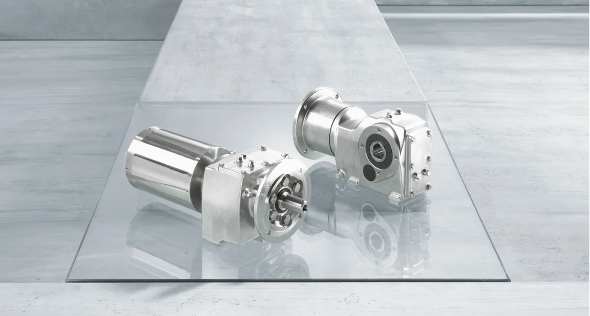

Servo reducers PSH.. CM2H.. : the solution for maximum hygiene requirements

At the same time, SEW USOCOME has also introduced stainless steel servo drives.

PSH . CM2H.. Hygienic Design meets the strict EHEDG (European Hygienic Engineering Design Group) guidelines as well as the US FDA guidelines for food and pharmaceutical products. Without rough edges or sharp edges, they are the ideal solution in environments with maximum hygiene requirements.

The high demands on service life and ease of cleaning give these compact units, consisting of a synchronous servo motor and planetary gearbox, the necessary properties of resistance to hot steam and corrosive cleaning products.

They can be controlled by all of our MOVI-C® generation electronic solutions.

Servo drives in stainless steel PSH.. CM2H.. in execution Hygienic Design

Put your energy into saving!

In the context of constant cost increases, SEW USOCOME offers solutions to reduce your consumption by up to 50%! As a leader in energy efficiency, managing your energy is our priority.

Synchronous motors DR2C.. , THE IE5 solution

Variable speed drives offer significant energy savings. The new synchronous motors of the DR2C series.. are the perfect example. These motors offer you many advantages for sustainable operation and cost reduction over the entire life cycle.

Compatible with the various SEW modular systems; with or without reducer, with a cabinet speed controller or a decentralised drive, this solution achieves the best efficiency class IE5 and thus makes it possible to achieve a high energy efficiency system. Energy losses can be 50% lower for some operating points than those with an IE3 network direct motor. In addition, their small footprint and their integration in the most varied applications are two major assets. At the same power, DR2C.. motors can be smaller up to two sizes than comparable IE3 asynchronous motors.

These three-phase engines also have a lower CO2 footprint.

Based on the DRN standard range, these engines offer a perfect fit with our standards, while being distinguished by their robustness and exceptional durability.

A quick return on investment with the MOVIGEAR® mechatronic solution!

With our MOVIGEAR® units, you can achieve energy savings of up to 50% on your installation thanks to the perfect combination of the IE5 efficiency class engine, high efficiency gearbox and integrated electronics. Perfectly synchronized elements that generate an efficient performance of the overall system. As a result, MOVIGEAR® mechatronic drive solutions are cost-effective, compact and power-optimized complete solutions.

These solutions can now be equipped with a HCP200 coating for wet areas that is particularly resistant to washing with aggressive detergents. Stainless steel screws and shafts complete the device.

Use energy efficiently with Power and Energy Solutions

With our new Power and Energy Solutions (PES), you’ll have a complete system that combines MOVI-C® control and drive technologies with specially sized modules for intelligent power and energy management. Among these many advantages: PES can divide by six the energy intensity peaks at the start of a load; it is able to restore energy in the network. It also saves space and significantly reduces costs by reducing the cable cross-section. In addition, in the event of a power failure, the energy reserve will allow your machine to complete its trajectory safely and therefore increase the service rate of your facilities and machines. True all-terrain, the Power and Energy Solutions solution adapts to all voltages, all frequencies and communicates with all your networks. A flexible, drawer solution, with an approach adapted to each customer need.

In short, PES is the ideal solution to manage electricity consumption more efficiently, storing energy and reusing it when necessary, thus ensuring the operational continuity of the installation. Your operating bill is reduced.

Our engineers are available to guide you through this selection.

Save money easily, focus on sustainability