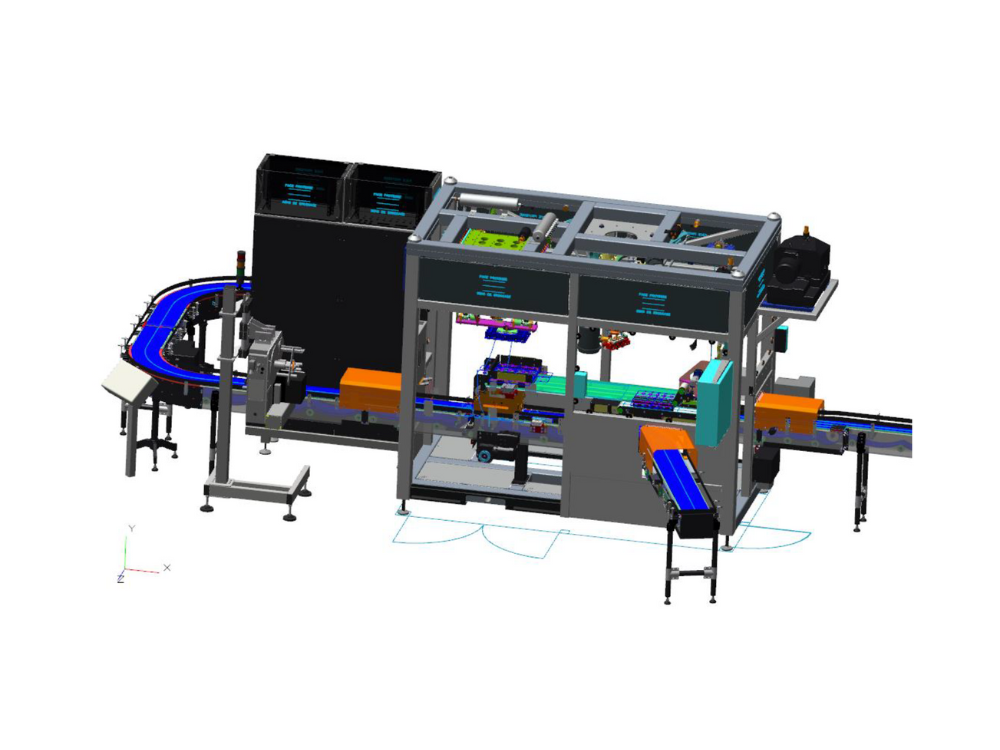

Compact realignment and encasing island CLS20 |

ARP

This concept makes it possible to process blister packs of 4, 6 or 8 jars, made available from a single-line conveyor.

The CLS20 is designed to manage products with or without clusters and its timing process will automatically adapt to the unit of sale processed, whether it is «bulk» or overpacked products on 1, 2 or three levels.

You treat pots of different heights on your conditioner; this is not a handicap! The CLS20 also responds to this constraint efficiently and without increasing the time required for format changes.

The island integrates a cadenceur produced with Brushless motorization, a 4-axis Delta dose preparation robot and a 2-axis Delta robot for encasing.

They are robots of our design; we master and guarantee the entire solution and its operation.

Format change time less than 5 minutes achievable without tools is repeatable in time.

Technical efficiency of 99%.

The CLS 40, 60 or 80 will meet higher rates of up to 80,000 pots/hour.