Modernization Without Replacement: Normandise Pet Food Adopts Bosch Rexroth's REMAN |

REXROTH BOSCH GROUP

This family-owned company based in Vire, Normandy, processes 150 tons of meat daily into food for cats and dogs. Faced with the natural wear of 20-year-old packaging machines, it was looking for an alternative to new component purchases — one that could reduce production downtime and ensure equipment sustainability.

A Concrete Answer to Performance and Sustainability Challenges

In the face of environmental pressures and supply chain tensions, Bosch Rexroth supports manufacturers through REMAN, its industrial remanufacturing offer. This is a standardized and industrialized process that goes far beyond simple repair. It includes a comprehensive inspection, preventive replacement of wear parts, and technological upgrades where possible.

The solution is part of the Bosch Group's circular economy strategy, aiming to combine industrial performance with reduced environmental impact.

Modernization Without Replacement

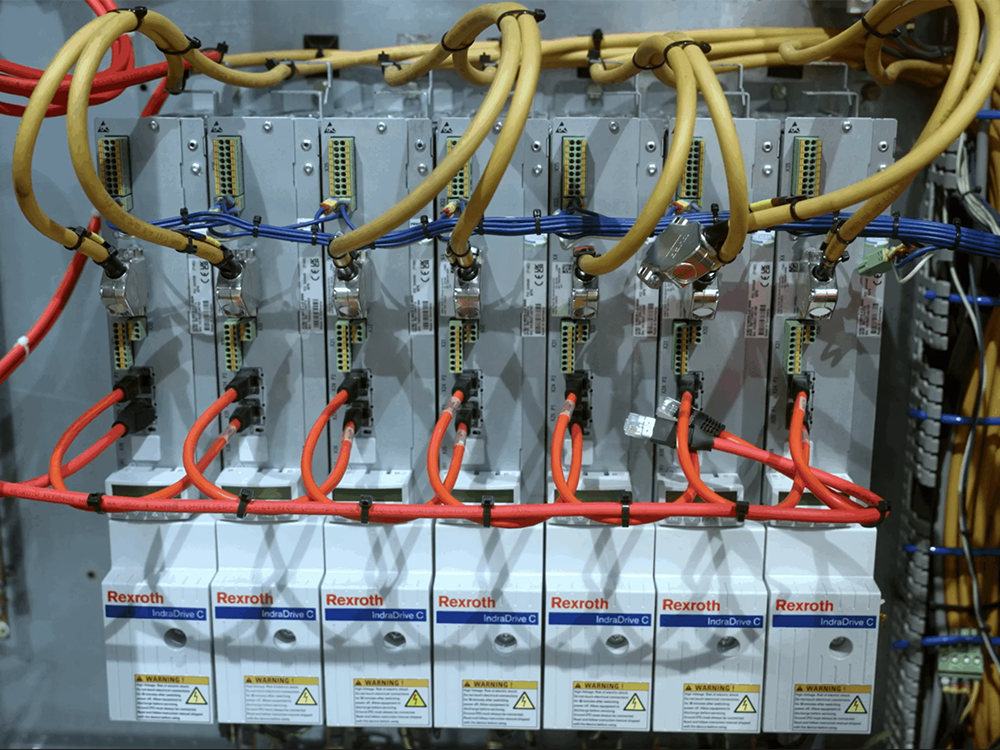

The intervention at Normandise Pet Food involved 25 motors and drive units, which were refurbished at Bosch Rexroth’s competence center. Meanwhile, identical spare parts ensured continuous production. The result: only 15 minutes of downtime during installation and 50% savings compared to full replacement.

“The REMAN process allowed us to modernize our equipment without compromising production. It was exactly the support we needed: a high-performance technical solution combined with a service adapted to our operational constraints.”

— François Duquesne, CEO of Normandise Pet Food

Encouraged by this successful first step, the company has already scheduled additional REMAN projects in 2025, covering two more production lines.

? Read the Bosch Rexroth article: Normandise Pet Food chooses remanufacturing with JYGA and Bosch Rexroth