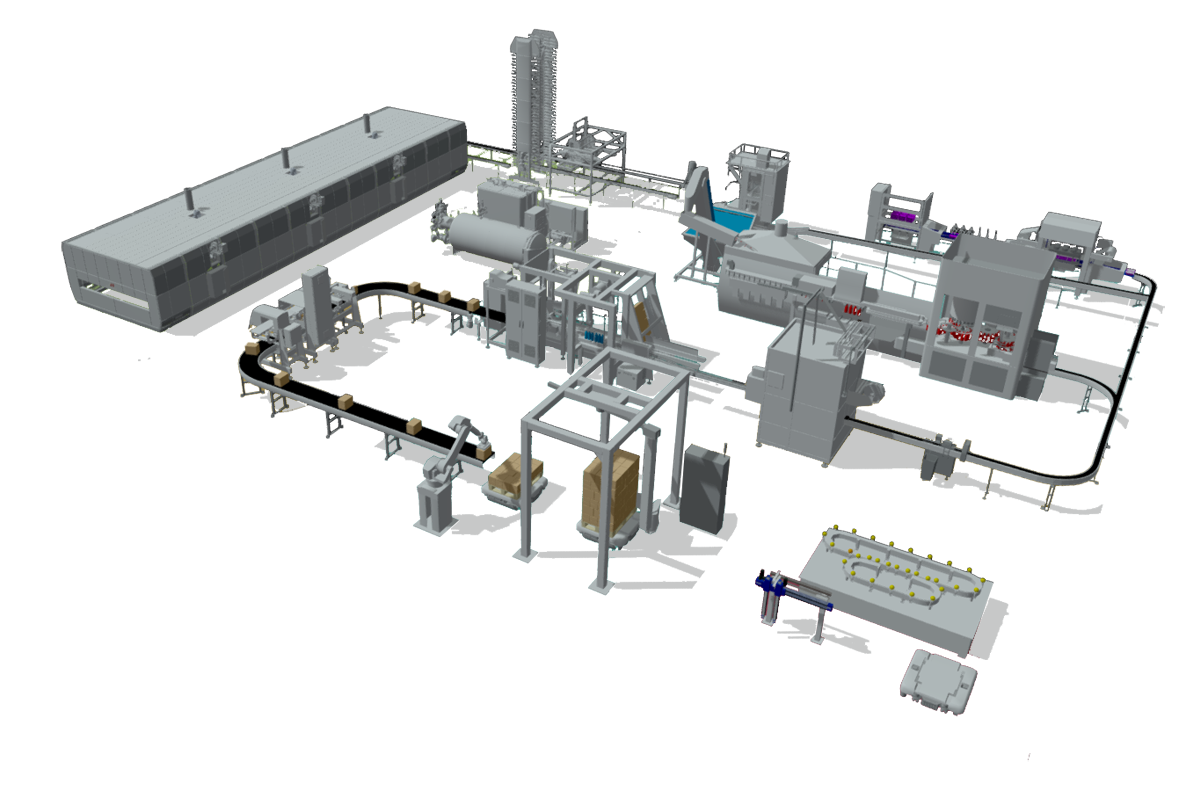

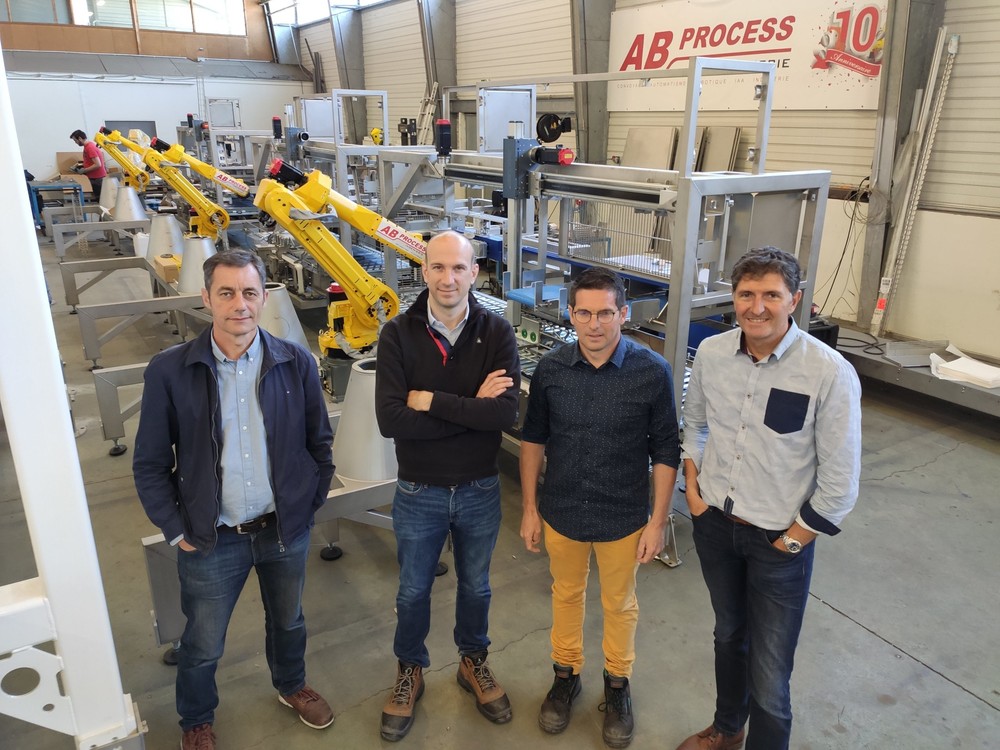

AB PROCESS INGENIERIE: As an integrator in industrial robotics, AB Process Engineering offers turnkey solutions for the automation of production lines.

AB Process Ingénierie is a company based in Brittany since 2008.

Our company has 13 years of expertise under its belt, more than 250 customers who have chosen AB Process Engineering, and more than 200 robots put into service in the last four years.

Today, AB Process Ingénierie installs 50 robots a year, which meet the needs of the food industry, as well as those of logistics, cosmetics and pharmaceuticals; in particular with solutions for conveying, case packing and pick-and-place, palletising and depalletising, and the integration of special machines, which are at the heart of our expertise.

As an integrator in automation and industrial robotics, the company designs, manufactures and installs high-performance, made-to-measure, turnkey solutions for the automation of production lines. As a long-term partner, AB Process Ingénierie accompanies you at every stage of your project, from defining your needs to the commissioning and maintenance of your installation.

Its mission? Helping manufacturers to make their production and logistics tools more efficient. Indeed, by automating our customers' installations, AB Process Ingénierie enables them to:

- Reduce the drudgery of their employees' work

- Solve their recruitment difficulties

- Increase their production capacity

- Improve their production quality

Innovation is at the heart of the company's installations. To ensure their quality and performance, it incorporates the latest technologies into its projects.

AB Process Ingénierie is proud of its origins, in particular its Made-in-France facilities thanks to the ‘French Fab’ label, and more particularly its Made-in-Brittany facilities as a member of the ‘Produit en Bretagne’ network since 2020.

Facilities / Services AB PROCESS INGENIERIE

Diversified expertise

AB Process Ingénierie is mainly involved in the food industry, but also in logistics, cosmetics and pharmaceuticals, where its teams develop solutions for the robotisation of your operations, and install machines specific to your products.

At the heart of its expertise are solutions for conveying, case packing, palletising and depalletising. To implement these solutions, a gripper adapted to your product and packaging is designed. To meet your needs, AB Process Ingénierie integrates special machines such as a scotch-taping machine, a stretch wrapping machine, a washer for products or boxes, a banding machine, a strapping machine, a cutting machine, a tipping machine or even a dosing machine.

The company can also integrate stacking, destacking and packaging solutions into your operations, tailored to your needs and your packaging.

It also offers more specific solutions, in particular for your cooking lines for traditional or rolled crêpes, as well as for herbs and seaweed.

Tailor-made solutions

The main objective is to work with you to develop the most relevant solution from a technical point of view, taking into account and respecting your needs, and adapting to your concerns.

Its teams design your machines, adapted to your process, taking into account all your constraints: space, temperature, dust, existing installations, production rates, budget, etc.

-

Depalletizing solution

Depalletizing solution

Depalletizing solution

Depalletizing solution

-

Palletizing solution

Palletizing solution

Palletizing solution

Palletizing solution

-

Palletizing solution

Palletizing solution

Palletizing solution

Palletizing solution

-

Pick and place solution

Pick and place solution

Pick and place solution

Pick and place solution

https://www.geppia.com/en/suppliers/item/366-ab-process-ingenierie#sigProId6e2b0c8a2d

AB Process Engineering: virtual reality for agri-food production lines

Friday, 31 January 2025Compact line capable of cashing doypacks of different formats in the United States

Monday, 04 March 2024Contact this company

Positioning on the line