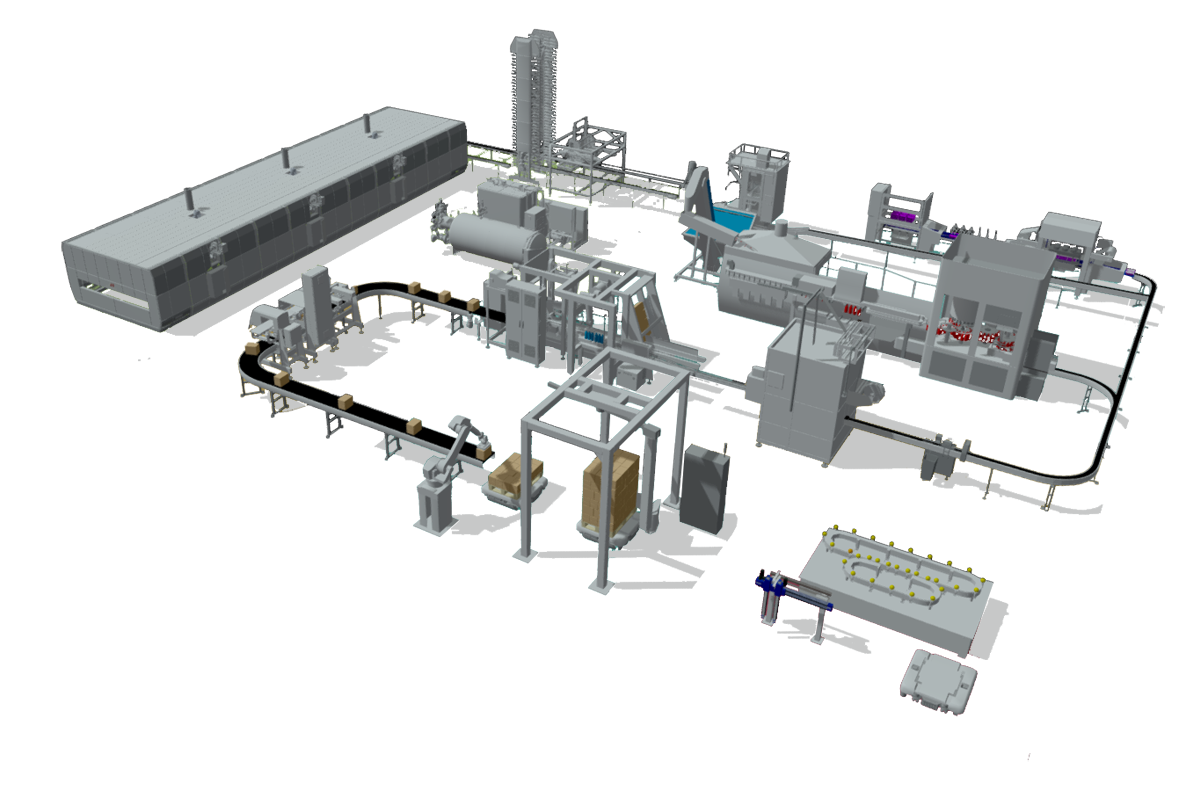

KARLVILLE: Vertically integrated machinery solutions for Shrink Sleeves, Pouches, Flexible Packaging, Tape & Handle Multipacks.

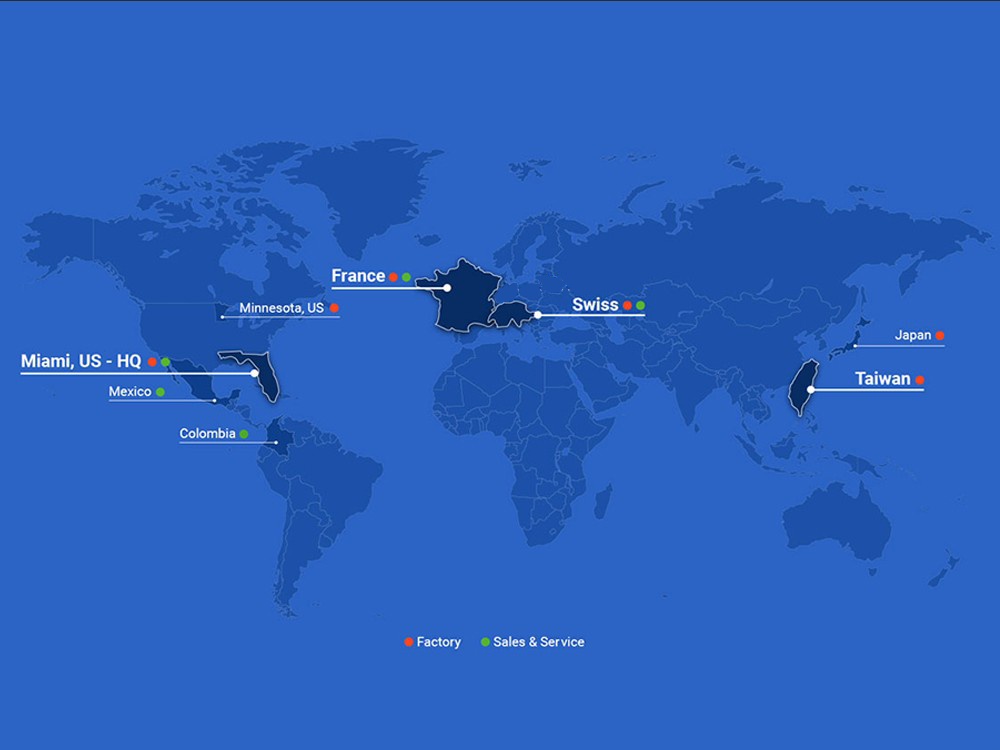

KARLVILLE was founded in 1996 by Raul Matos and John Price. Based in the United States, the group now has 8 production sites worldwide.

With the acquisition of Scheidegger in 2006, then of CEFMA two years later, the group has new technologies and therefore develops its ranges of machines. KARLVILLE has installed more than 3,500 machines in more than 86 countries. The support facilities in the United States, Europe and Asia make it possible to better serve their global customers.

KARLVILLE is committed to respecting the environment and works closely with its partners to offer you solutions tailored to the environmental challenges of your products.

Facilities / Services KARLVILLE

SLEEVE

SLEEVE

As a leading worldwide supplier of converting & labeling shrink sleeve machinery, Karlville offers its customers the support and expertise necessary to ensure the success of the whole project from machinery to labels to the finished product.

Karlville offers shrink sleeve lines including automatic shrink sleeve applicators, tamper evident applicators and shrink tunnels for different container requirements. These lines can be integrated to existing production lines or installed off-line based on customer request.

- Unique technologies servo driven offering high capacities such as 1200bpm for tamper evident and 800bpm for full body, both on single lane linear machines

- High Performance Hot Air Tornado Tunnel achieves steam-like quality

- Our applicator has been tested to run the latest sustainable solutions

FILL & CAP

FILL & CAP

The SPOUT Pro FC-1F is our new automatic pouch filling through-the-spout and capping machine. It can fill top and corner spouted pouches. It can be used for: food such as baby food, dips, hummus, sauces, peanut butter, honey, yoghurt, juices, alcoholic beverages or non-food such as gels, shampoo, lotions, soaps, conditioner, cleaners, softeners, automotive oils and adhesives.

This machine can be custom-designed and built with a range of different options according to your filling conditions, product(s) to fill and pouch/spout size(s).

- Compact filling lines up to 70ppm

- Ready for latest sustainable materials

- Offering top flexibility thanks to full servo-driven systems

FILL & SEAL

FILL & SEAL

Our new REVO Pro-1, engineered and patented by DolcePack Technology, is an innovative automatic pre-made pouch filling & sealing machine designed to be user friendly with a compact footprint and full-frontal accessibility to all process stations. Engineered to have high flexibility in various pouch types and sizes.

It is suitable for, food & non-food products in various forms including: solids, liquids, granules and powders.

Machine will be configured and built with a range of options according to customer product(s) to fill, filling condition(s), specific requirements, pouch size & type.

- Most compact and flexible plateform

- Top accessibility for operation and maintenance

- Top flexibility thanks to full servo driven systems

TAPE & MULTIPACK

TAPE & MULTIPACK

With CEFMAPACK trade mark, Karlville expanded its machinery offering to brand-owners worldwide with the widest range of carry-handle application systems as well as tape multi-packing machinery. CefmaPACK & CefmaHANDLE product lines offer diverse solutions for end of line tape packaging for pouches, bottles and boxes.

- Handle placement in most any position

- Tape multi-packaging is an economical and sustainable alternative such as paper adhesive up to 5kg

- In-line and off-line solutions to make multipacks of 2 to 6 products by holding together flow packs, trays, bags, boxes and cartons using clear or high-quality printed tape

-

BAO 202 automatic machine for tape bundling of multi packs in 1×2 and 1×3

BAO 202 automatic machine for tape bundling of multi packs in 1×2 and 1×3

BAO 202 automatic machine for tape bundling of multi packs in 1×2 and 1×3

BAO 202 automatic machine for tape bundling of multi packs in 1×2 and 1×3

-

SPOUT Pro FC-1F is our new automatic pouch filling thru the spout and capping machine

SPOUT Pro FC-1F is our new automatic pouch filling thru the spout and capping machine

SPOUT Pro FC-1F is our new automatic pouch filling thru the spout and capping machine

SPOUT Pro FC-1F is our new automatic pouch filling thru the spout and capping machine

-

REVO Pro-1 is an innovative automatic pre-made pouch filling & sealing machine

REVO Pro-1 is an innovative automatic pre-made pouch filling & sealing machine

REVO Pro-1 is an innovative automatic pre-made pouch filling & sealing machine

REVO Pro-1 is an innovative automatic pre-made pouch filling & sealing machine

-

P800 is a single head for a high-speed application of sleeve

P800 is a single head for a high-speed application of sleeve

P800 is a single head for a high-speed application of sleeve

P800 is a single head for a high-speed application of sleeve

https://www.geppia.com/en/suppliers/item/65-karlville#sigProIdcedbcfec85

Karlville at CFIA Rennes 2025: Innovation for bag-fillers

Friday, 31 January 2025Karlville opens its Lyon factory’s doors

Friday, 10 November 2023Karlville shares an award in an innovative project in the packaging sector

Friday, 15 April 2022Review of the Karlville France Open House

Friday, 03 December 2021Contact this company

Positioning on the line

Functions & Applications

10-E27

10-E27