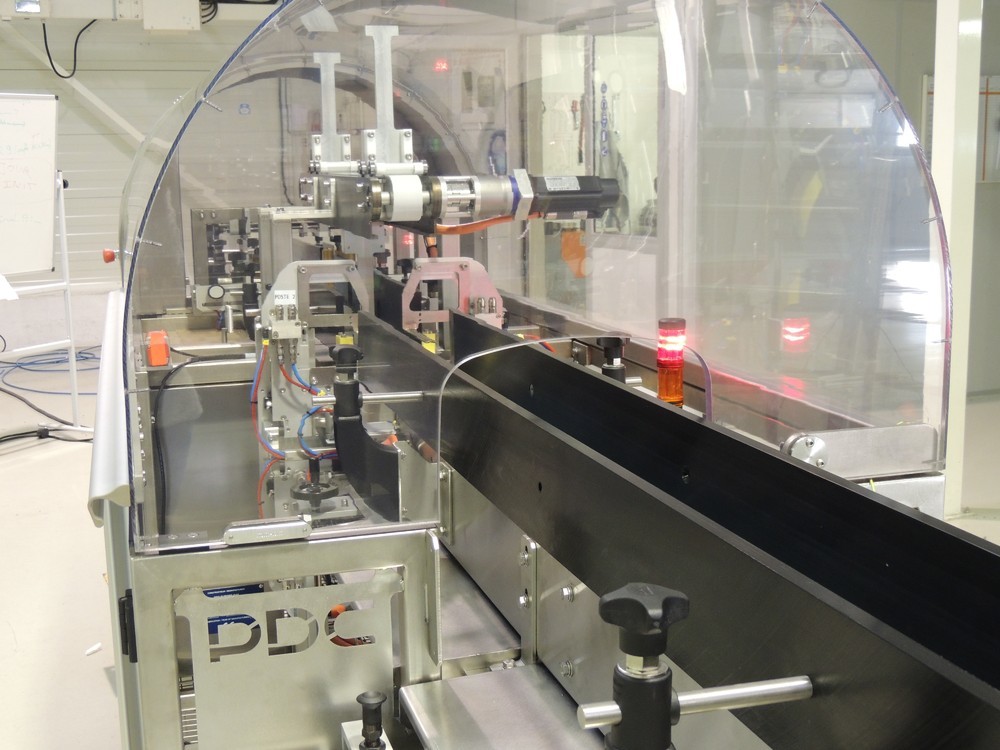

PDC EUROPE: Designer of industrial solutions. Sleeve applicators and peripheral systems ; Orientation & reject unit, pick & place robots

PDC Europe is a family business based in northern France since 1984. It has become a leading company in the manufacturing of sleeve applicators.

PDC Europe has installed, over the years, more than 3000 shrink and stretch sleeve applicators around the world, addressing decoration, tamper evidence and bundling applications. The company's machines are specifically designed to meet the needs of food, drink, pharmaceutical, cosmetic, homecare and industrial sectors. This success is due to an intensive innovation strategy, allowing them to provide custom-made machines. Their production is 100% made in France.

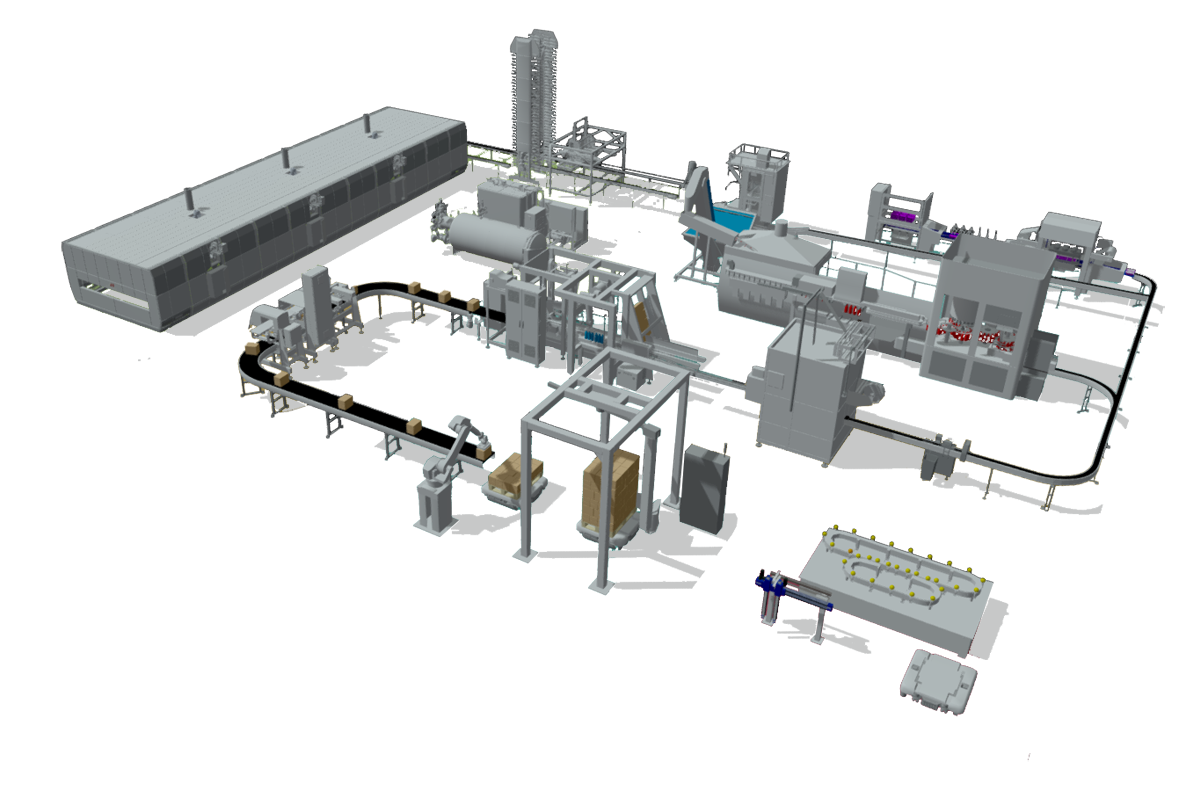

At PDC Europe, their business model is vertical integration, meaning they manage internally every step of your project: machine design & automation, parts manufacturing, assembly, tuning, installation, maintenance.

They now offer a wide range of innovative solutions designed for your production lines. Based on their experience, they now supply conveyors (Vector), robots (PDC Robotics) and a brand new patented reject unit “SURE”.

They have also worked lately with a French designer to improve the aesthetics of their machines and the access to all moving parts in order to simply troubleshooting, reduce maintenance time and costs.

More than 50% of their applicators' subassemblies are based on standard designs. This allows them to answer quickly and safely, while still adapting the key features to your expectations! Custom-made machines with safe delivery and process.

Facilities / Services PDC EUROPE

The sleeve is a plastic film whose two ends have been welded together to create a tube designed to partially or totally cover all types of containers. It is used as an alternative to labels and secondary packaging in cardboard and is currently the only solution for decorating containers with complex shapes. The "sleeve" is a great marketing tool that offers a real differentiation of your products from the competition

Advantages

The "sleeve" is compatible with all shapes and materials and does not require the use of glue.

- It is not affected by humidity or temperature changes.

- It is totally customizable (totally or partially printable, transparent, matte or glossy, smooth or textured)

- It offers a 360° communication surface that no other label can match.

- Shrink & stretch sleeves

There are 2 types of sleeves, the heat-shrink sleeve and the stretch sleeve. Made from different materials, they both offer a wide range of possibilities and can be perfectly adapted to your needs.

PDC Europe specializes in sleeve application machines, both stretch and shrink. As far as the sleeves are concerned, there are two main ranges of machines, stretch and shrink.

What is the stretch sleeve?

The stretch sleeve is made of PE plastic, high or low density. The stretch sleeve does not require glue or heat to hold the containers and is easily adapted to most materials (plastics, glass, metal, polystyrene, etc.). It can be applied to a wide range of products from 100ml to 200L.

Its main advantages: its high recyclability rate, the savings in materials and costs that it generates and the communication surface that it offers.

How is a stretch sleeve applied?

Stretch sleeve technology allows you to apply a sleeve to your product using arms that will stretch the plastic over the container. This method is very efficient, and depending on the model of the 4 stretch sleeve machines of PDC Europe, can provide you with many advantages.

If you do not find what you are looking for in these two categories, PDC Europe even offers a "special applications" range, composed of three machines that will take care of particular production cases.

What is a shrink sleeve?

The shrink sleeve can be applied on most types of materials (plastic, glass, metal, polystyrene,...) and adapts to all shapes, even the most complex ones.

How is a shrink sleeve applied?

The shrink sleeve is larger than the product - it is by heating that it will take the shape of the product. The extrusion technology locks the sleeve into one configuration (dimension and thickness). When the sleeve is heated, its tensions are released and it shrinks and thickens.

Manchonnage

-

Stretch sleeve applicator : HORIZON PDC Europe

Stretch sleeve applicator : HORIZON PDC Europe

Stretch sleeve applicator : HORIZON PDC Europe

Stretch sleeve applicator : HORIZON PDC Europe

-

PDC Europe Workshop

PDC Europe Workshop

PDC Europe Workshop

PDC Europe Workshop

-

ESTEC Machine

ESTEC Machine

ESTEC Machine

ESTEC Machine

-

R250 PDC Europe

R250 PDC Europe

R250 PDC Europe

R250 PDC Europe

https://www.geppia.com/en/suppliers/item/75-pdc-europe#sigProId59a2ba4a1c

PDC Europe: Empowered by Innovation

Wednesday, 16 November 2022Contact this company

Positioning on the line

Functions & Applications

HALL 15 / E57-4

HALL 15 / E57-4