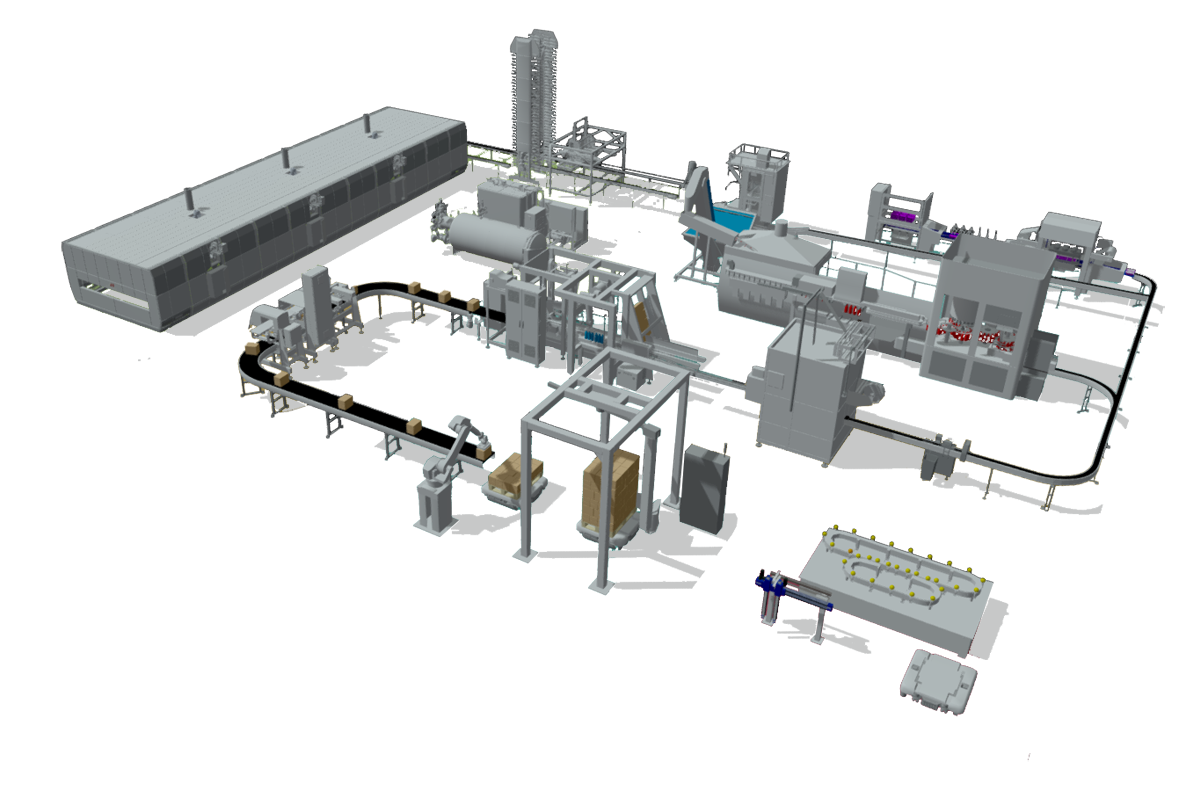

THIMONNIER: French designer and manufacturer of packaging machines for flexible pouches

Located in the region of Rhône-Alpes in France (to the north of Lyon), the company was originally created with the invention of the sewing machine in 1830. Thimonnier is now specialized in the design and manufacturing of flexible packaging machines for liquid, pasty, and viscous products in pillow pouches, pre-made DOYPACK®, spouted stand-up pouches, inverted pouches for fresh and dairy products (milk, yogurt, cheese...), fruit juices, purees, bleach berlingots (in doses), medical pouches, etc.

Today, Thimonnier is a world leader in design and manufacturing of machines allowing to fill flexible pouches, premade DOYPACK®, spouted stand-up pouches, inverted pouches, pillow pouches, berlingots and rigid shells. The company has more than 80 employees in its staff and exports in over 150 countries.

Thier expertise, based on technical skills in sealing technologies :

- Impulse sealing

- Thermal sealing

- High-frequency sealing

- Ultrasonic sealing

Which allows them to provide the best solution for all your packaging projects.

Facilities / Services THIMONNIER

Eager to adapt to a market in constant evolution, Thimonnier offers its experience in a wide range of industries:

- Food industry( liquid and viscous fresh and dairy products, with or without pieces)

- Detergents (liquid soap, liquid bleach)

- Medical industry (intravenous solutions in IV bags, prostheses, paramedical products)

- Cosmetics (stationery, leather goods, childcare, clothing)

- Packaging (thermoformed blisters)

- Sealing machines for large-capacity bags

6 COMPLETE RANGES OF MACHINES

- FILLING SEALING MACHINES FOR DOYPACK® & INVERTED POUCHES:

- From 2 to 240 pouches per minute

– Pouch volumes from 50 ml to 5 liters

– Pre-made stand up pouches, spouted DOYPACK®, inverted pouch

– Impulse, ultrasonic or thermal sealing

– Hot filling

– Ultra-clean version (ESL)

- VERTICAL FILLING AND PACKAGING MACHINES FOR PILLOW POUCHES:

– From 5 to 200 pouches per minute

– Pouch volumes from 30 ml to 5 litres

– LDPE film with or without barrier [EVOH, …]

– Impulse, thermal or ultrasonic sealing

– Ultra-clean, E.S.L. [Extended Shelf Life] and aseptic version

- VERTICAL PACKAGING MACHINES FOR CONCENTRATED PRODUCTS IN BERLINGOT:

- From 1800 to 3000 berlingots per hour

– Pouch volumes from 50 ml to 500 ml

– From PVC, EVA or PE film

– Radio frequency or thermal sealing

- VERTICAL FORM / FILL / SEALING MACHINE FOR MEDICAL POUCHES

– Production and filling of PVC/EVA bags from 50 ml to 5000 ml - – Sealing of thermoformed shells in PETG/BAREX or other materials with heat-sealable varnish and TYVEK/FSL/Complex lids

- RADIO FREQUENCY MACHINES:

- – THIMONNIER designs and manufactures High-Frequency generators with power ranges from 400 W to 30 kW, in compliance with current CE-CEM (Electromagnetic Compatibility) regulations

- MANUAL & SEMI-AUTOMATIC DEVICES

Form-Fill-Seal

Ultra-clean filler/screwdriver for DOYPACK® and inverted pouches

Tuesday, 05 March 2024Contact this company

Positioning on the line

Functions & Applications

10-C28

10-C28